The story starts with a car that just won’t start. It’s a common problem, and one that can be frustrating for both the owner and the mechanic. But in the world of modern cars, the culprit behind this problem could be the timing of your OBD II engine. What exactly does that mean, and how do you fix it?

This guide will help you understand the process of timing an OBD II engine, offering a detailed explanation and even some insightful tips from automotive professionals.

The Importance of Engine Timing

Imagine a finely orchestrated symphony where every instrument plays in perfect harmony. An engine is much like that orchestra, where each component needs to operate in perfect sync to achieve optimal performance.

Engine timing, in simple terms, is the precise coordination of the crankshaft, camshaft, and valves to ensure that fuel is delivered and ignited at the right moment.

Why Does Engine Timing Matter?

The timing of an engine is crucial for a multitude of reasons:

- Fuel Efficiency: Correct timing ensures the engine burns fuel efficiently, resulting in better fuel economy and less harmful emissions.

- Power and Performance: Improper timing can lead to loss of power, sluggish acceleration, and reduced overall performance.

- Engine Durability: Mistiming can cause engine damage, including pre-ignition, detonation, and even engine failure.

Understanding OBD II Engines and Timing

OBD II (On-Board Diagnostics II) is a standard adopted by the US government in 1996 for all cars and light-duty trucks. This system, embedded in the vehicle, monitors the engine’s performance and provides diagnostic information through a standard connector called the OBD II port.

Timing an OBD II Engine: A Deeper Dive

Timing an OBD II engine is a more complex process than its predecessors. It involves using specialized tools and a deep understanding of the engine’s electronic control system. Here’s a breakdown of the process:

- Diagnosis: The first step involves diagnosing the problem using an OBD II scanner. This tool helps identify any codes related to timing issues, such as misfires or knock sensor problems.

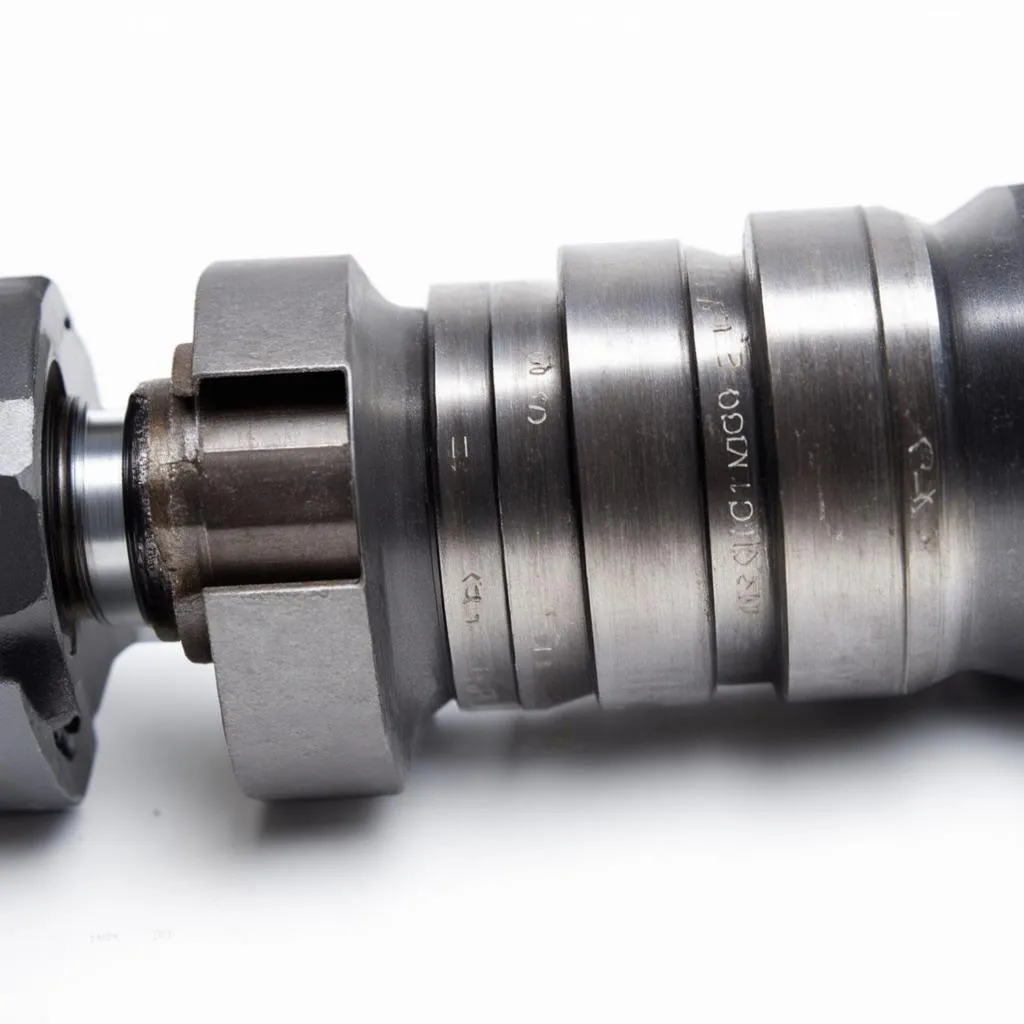

- Timing Belt/Chain Inspection: OBD II engines utilize either a timing belt or chain to synchronize the crankshaft and camshaft. A visual inspection is crucial to ensure the belt or chain is in good condition, without any signs of wear or damage.

- Cam Timing Alignment: This step involves aligning the camshaft and crankshaft to the manufacturer’s specifications. It’s often done using timing marks or tools specifically designed for the engine type.

- Ignition Timing Adjustment: Modern OBD II engines typically have an electronic ignition system. Adjusting the timing involves using a scan tool to access the engine control module (ECM) and make necessary adjustments. This involves setting the spark advance to achieve the desired timing for optimal performance.

Troubleshooting Common Issues and Solutions

Here are some common issues you might encounter while attempting to time an OBD II engine:

Problem: The engine won’t start after timing adjustments.

Solution: Double-check the timing marks and ensure they’re correctly aligned. Also, verify the ignition system is working properly, checking for spark and fuel delivery.

Problem: The engine runs rough or has poor performance after timing changes.

Solution: This indicates a potential mistiming issue. Recheck the timing marks and ensure they are precisely aligned. You might also want to adjust the ignition timing slightly to see if it improves performance.

Frequently Asked Questions

Q: Do I need a professional mechanic to time an OBD II engine?

A: While it’s possible to time an OBD II engine yourself, it requires advanced skills and specialized tools. Unless you have experience and the right equipment, it’s advisable to leave it to a professional mechanic.

Q: How often should I check the timing of my OBD II engine?

A: Timing belt or chain replacement intervals vary depending on the vehicle manufacturer. Consult your owner’s manual or a qualified mechanic for the recommended service schedule for your specific vehicle.

Q: Can I use a regular OBD II scanner to check the engine timing?

A: While basic OBD II scanners can provide information about engine codes and sensor readings, they don’t typically have the capability to check the precise timing of the engine. Specialized timing tools are required for this purpose.

Resources and Further Information

For more detailed information and technical specifications, you can consult your owner’s manual or resources from reputable automotive websites like techcarusa.com.

Need Help? Contact Us!

If you’re facing difficulties timing your OBD II engine, don’t hesitate to reach out. We have a team of experienced automotive professionals available 24/7 to provide expert assistance. Contact us on Whatsapp: +84767531508.

Conclusion

Timing an OBD II engine can be a complex task, but it’s essential for ensuring optimal engine performance and longevity. By understanding the process, identifying potential issues, and seeking professional help when needed, you can keep your vehicle running smoothly and enjoy a seamless driving experience.

Remember: A well-timed engine is like a well-played symphony, where every component works in harmony to create a beautiful and efficient experience.

Don’t forget to leave a comment below if you have any questions or share your own experiences with timing an OBD II engine! And be sure to check out our other articles on techcarusa.com for more automotive insights and tips.

timing-belt-inspection

timing-belt-inspection

obd-ii-scanner-diagnostic-tool

obd-ii-scanner-diagnostic-tool

engine-timing-alignment

engine-timing-alignment