As a vehicle owner, especially if you manage a fleet, encountering a “Check Engine” light can be unsettling. This light is often accompanied by OBD2 codes, which might seem like cryptic messages from your vehicle. But don’t worry, understanding these codes is simpler than you might think and incredibly useful for maintaining your vehicle’s health.

In this comprehensive guide, we’ll demystify OBD2 codes. We’ll explain what they are, how they work, the different types, and most importantly, how to understand and fix the issues they indicate. Whether you’re a seasoned mechanic or a new car owner, this guide will equip you with the knowledge to confidently handle OBD2 codes and keep your vehicles running smoothly.

Decoding OBD2 Codes: Your Vehicle’s Diagnostic Language

On-Board Diagnostics II (OBD2) codes are essentially a standardized language used by your vehicle’s computer system to communicate potential problems. Think of them as error messages from your car, alerting you to issues that need attention.

Modern vehicles are equipped with a sophisticated network of sensors and modules that constantly monitor various systems, from the engine and transmission to the emissions and braking systems. When these systems detect a malfunction or reading outside the normal parameters, the vehicle’s computer generates a specific OBD2 code.

These codes are designed to be informative, pointing towards the area of the problem, ranging from minor glitches to significant mechanical failures. The illumination of the “Check Engine” light on your dashboard is often the first sign that an OBD2 code has been triggered, indicating that something within your vehicle’s engine or related systems isn’t operating as expected.

To access these codes, you’ll need an OBD2 scanner or code reader. This tool easily connects to your vehicle’s OBD2 port, typically located under the dashboard on the driver’s side. Once connected, the scanner retrieves the stored trouble codes, presenting them as alphanumeric codes that pinpoint the source of the issue. These codes act as a crucial starting point, guiding you or your mechanic in diagnosing and resolving the problem effectively. For fleet managers, understanding and utilizing OBD2 codes is invaluable for proactive vehicle maintenance and minimizing downtime.

What OBD2 codes mean

What OBD2 codes mean

Navigating the Different Types of OBD2 Codes

When an OBD2 code appears for one of your vehicles, identifying its type is the first step towards effective troubleshooting. OBD2 codes are categorized into four main types, each relating to a specific area of the vehicle. Recognizing these categories will streamline your diagnostic process and help you address issues more efficiently.

Powertrain Codes (P-Codes)

Powertrain codes, starting with the letter ‘P’, are the most common type of OBD2 codes. They indicate problems within the powertrain system, which encompasses the engine, transmission, and related drivetrain components. These codes are crucial for understanding issues that directly affect your vehicle’s power and performance.

For example, a prevalent powertrain code is P0300, indicating “Random/Multiple Cylinder Misfire Detected.” This code suggests that one or more cylinders in the engine are not firing correctly. Potential causes can range from faulty spark plugs or ignition coils to fuel delivery problems or vacuum leaks. Addressing a P0300 code promptly is essential as persistent misfires can lead to reduced fuel efficiency, engine damage, and increased emissions.

Body Codes (B-Codes)

Body codes, beginning with ‘B’, signal problems within the vehicle’s body systems. These systems include components like airbags, power windows, electronic mirrors, lighting, and the climate control system. While body codes might not directly impact the vehicle’s driving performance, they relate to comfort, convenience, and safety features.

For instance, a B1001 code might indicate an issue with the Restraint System Malfunction Indicator Lamp Circuit. This could mean a problem with the circuit controlling the airbag warning light. While it may seem minor, issues within the restraint system, particularly airbag circuits, should be addressed immediately to ensure all safety features are functioning correctly.

Chassis Codes (C-Codes)

Chassis codes, starting with ‘C’, relate to issues within the vehicle’s chassis systems. This category includes components like the anti-lock braking system (ABS), traction control, electronic stability control, and steering and suspension systems. Chassis codes are particularly important as they often relate to safety and vehicle handling.

For example, a C0045 code could indicate a problem with the Rear Right Wheel Speed Sensor Circuit. A malfunctioning wheel speed sensor can affect ABS and stability control systems, potentially compromising braking performance and vehicle stability, especially in emergency situations or slippery conditions.

Network or Communication Codes (U-Codes)

Network communication codes, beginning with ‘U’, indicate problems within the vehicle’s communication network. Modern vehicles use complex communication networks to allow various electronic control units (ECUs) and modules to communicate with each other. U-codes signal disruptions in this communication process.

A common U-code is U0100, “Lost Communication With ECM/PCM.” This code signifies a loss of communication with the Engine Control Module (ECM) or Powertrain Control Module (PCM), which are essentially the brains of the engine and powertrain management systems. Communication issues can be caused by wiring problems, faulty modules, or network issues, and can lead to a wide range of symptoms, affecting multiple vehicle systems.

Understanding these four main categories of OBD2 codes is crucial for narrowing down the potential problem area and initiating the correct diagnostic and repair procedures.

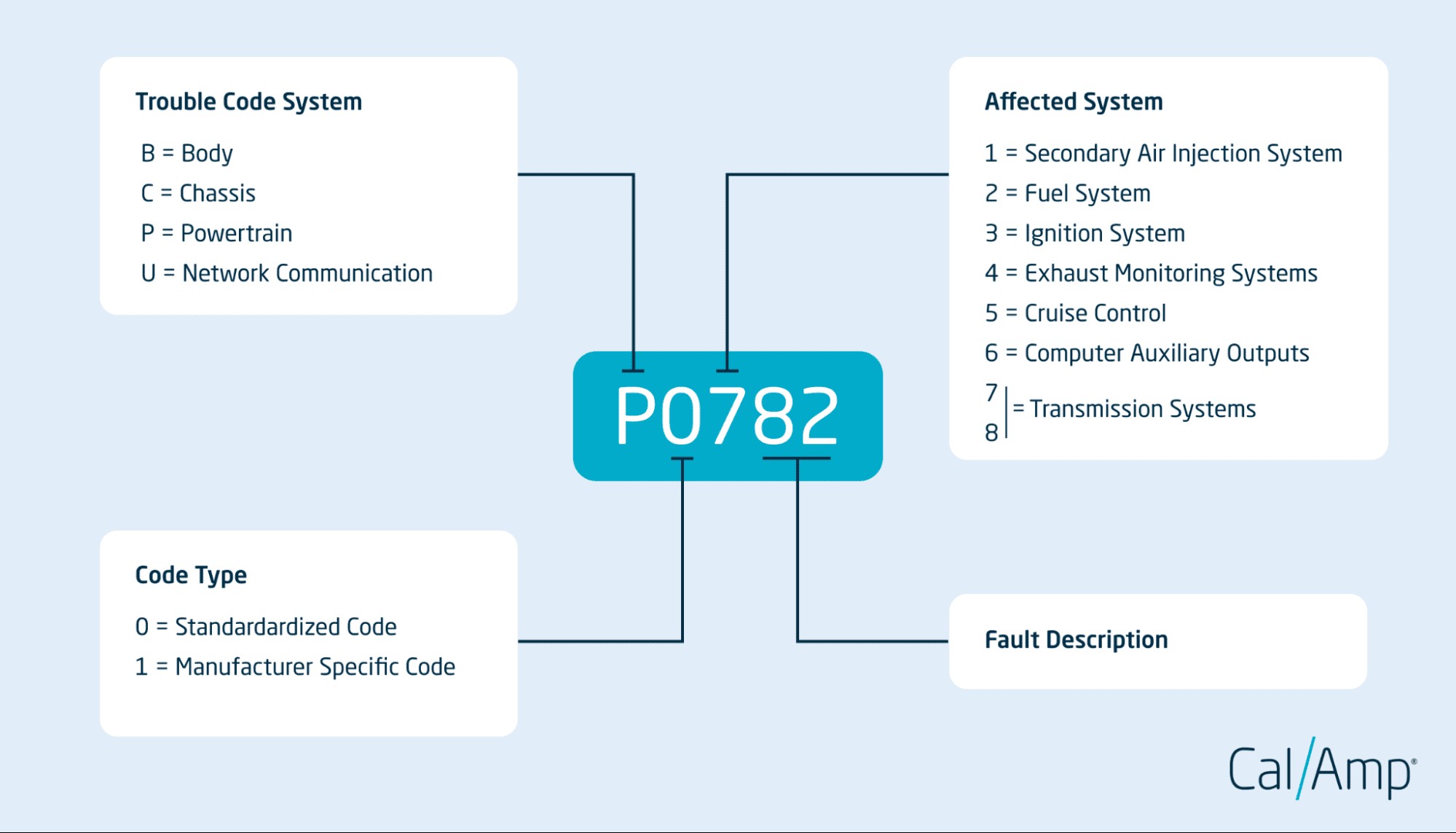

Decoding the Anatomy of an OBD2 Code

OBD2 codes are not random strings of characters; they follow a structured format that provides valuable information when deciphered. Each code is five characters long, consisting of a letter followed by four digits. Understanding this structure can significantly aid in diagnosing vehicle problems.

[Replace with an image illustrating the OBD2 code structure if you have one, or consider creating a simple graphic. If not, remove this line.]

Let’s break down each position in a typical OBD2 code:

-

First Character: Code Type

- P – Powertrain (Engine, Transmission, Drivetrain)

- B – Body (Airbags, Windows, Lighting, etc.)

- C – Chassis (ABS, Brakes, Suspension, Steering)

- U – Network Communication (Communication Systems)

-

Second Character: Code Subtype

- 0 – Generic or Standardized Code (SAE defined, common to all manufacturers)

- 1, 2, 3 – Manufacturer-Specific Code (Defined by the vehicle manufacturer, more specific to the brand)

-

Third Character: Affected System

This digit indicates the specific system within the category (Powertrain, Body, Chassis, or Network) that is experiencing the problem. The common affected systems are:- 1 – Fuel and Air Metering

- 2 – Fuel and Air Metering (Injector Circuit)

- 3 – Ignition System or Misfire

- 4 – Auxiliary Emission Controls

- 5 – Vehicle Speed Controls and Idle Control System

- 6 – Computer Output Circuit

- 7, 8 – Transmission

-

Fourth and Fifth Characters: Specific Code

These last two digits are specific numerical identifiers that pinpoint the exact nature of the fault within the identified system. For example, in the code “P0420”, ‘420’ specifies “Catalyst System Efficiency Below Threshold (Bank 1)”.

Example: Decoding P0301

- P – Powertrain (Engine related)

- 0 – Generic Code (Standardized)

- 3 – Ignition System or Misfire

- 01 – Specific code for Cylinder 1 Misfire

By understanding this structure, you can start to interpret OBD2 codes even before using a scanner’s detailed description. This knowledge empowers you to quickly understand the general area and nature of the problem.

How to Read OBD2 Codes: Tools and Techniques

Reading OBD2 codes is a straightforward process, primarily requiring an OBD2 scanner. These scanners are readily available online and at auto parts stores, ranging from basic handheld units to more advanced professional-grade tools.

Steps to Read OBD2 Codes:

-

Locate the OBD2 Port: The OBD2 port is typically located under the dashboard on the driver’s side of most vehicles. It’s usually within easy reach and doesn’t require any tools to access. Refer to your vehicle’s owner’s manual if you have trouble locating it.

-

Connect the OBD2 Scanner: Turn off your vehicle’s ignition. Plug the OBD2 scanner into the OBD2 port. Ensure it’s firmly connected.

-

Turn Ignition to ‘ON’ Position (Engine Off): Turn the ignition key to the ‘ON’ position, but do not start the engine. This provides power to the vehicle’s computer and the OBD2 scanner.

-

Power On the Scanner and Read Codes: Turn on the OBD2 scanner. Follow the scanner’s instructions, typically involving selecting options like “Read Codes” or “Diagnostic Codes.” The scanner will communicate with the vehicle’s computer and display any stored OBD2 codes.

-

Record the Codes: Write down all the codes displayed. Note them accurately, as even a single digit difference can indicate a different problem.

-

Use the Scanner’s Definition Feature (If Available): Many OBD2 scanners have a feature to provide a brief description of the code. Use this function to get an initial understanding of what each code means.

-

Consult a Reliable OBD2 Code Database: For more detailed information, use online OBD2 code databases or mobile apps. Websites like OBD-Codes.com or the National Institute for Automotive Service Excellence (ASE) website offer comprehensive information on OBD2 codes, including possible causes, symptoms, and troubleshooting steps.

Choosing the Right OBD2 Scanner:

- Basic Scanners: These are inexpensive and read and clear codes. Suitable for basic diagnostics.

- Mid-Range Scanners: Offer additional features like live data streaming, freeze frame data, and sometimes enhanced code definitions. Good for DIYers and enthusiasts.

- Professional Scanners: These are more expensive and offer advanced features like bidirectional controls, advanced diagnostics, and access to manufacturer-specific codes. Used by mechanics and advanced users.

Safety Precautions:

- Always read the scanner’s manual before use.

- Do not operate the scanner while driving.

- Ensure the vehicle is parked in a safe location when performing diagnostics.

Reading OBD2 codes is the first step in diagnosing and resolving vehicle issues. Combined with a little research, it can save you time and money by providing valuable insights before you consult a mechanic.

Clearing OBD2 Codes: When and How (and When Not To)

Clearing OBD2 codes might seem like a quick fix, but it’s crucial to understand when it’s appropriate and when it’s not. While it can turn off the “Check Engine” light, simply clearing a code without addressing the underlying issue is rarely a long-term solution and can even mask more serious problems.

When Clearing OBD2 Codes Might Be Appropriate:

- After Repairing the Issue: Once you’ve diagnosed the problem indicated by the OBD2 code and completed the necessary repairs, clearing the code is appropriate. This resets the system and turns off the “Check Engine” light. If the repair was successful, the code should not reappear.

- False Alarm or Intermittent Issue: In some cases, a code might be triggered by a temporary glitch or sensor malfunction that resolves itself. If you’ve checked for obvious issues and suspect a false alarm, clearing the code can be done to see if it returns. However, if the code reappears, further investigation is needed.

- Emissions Testing Prerequisite: Some vehicles require the OBD2 system to complete a “drive cycle” and have all emission monitors set to “ready” before passing an emissions test. Clearing codes resets these monitors, and a drive cycle may be needed afterward. (Note: Clearing codes just before an emissions test is generally not advisable if there are underlying issues, as the codes and “Check Engine” light will likely return).

Methods to Clear OBD2 Codes:

-

Using an OBD2 Scanner:

- Connect the scanner to the OBD2 port and turn the ignition to the ‘ON’ position (engine off).

- Navigate the scanner’s menu to find the “Clear Codes,” “Erase Codes,” or similar option.

- Follow the scanner’s prompts to clear the codes.

- After clearing, the “Check Engine” light should turn off.

-

Disconnecting the Battery (Less Recommended):

- Caution: This method is less precise and can reset other vehicle systems, including radio presets and security systems. It’s generally not recommended unless you are familiar with the potential side effects for your specific vehicle.

- Disconnect the negative battery terminal for about 10-15 minutes.

- Reconnect the battery. This may clear some OBD2 codes, but it’s not as reliable as using a scanner.

When You Should NOT Clear OBD2 Codes:

- Without Diagnosing and Repairing the Problem: Clearing a code without fixing the underlying issue is like silencing an alarm without addressing the fire. The problem will likely persist or worsen, and the code will likely return.

- Before an Emissions Test (If There’s an Issue): Clearing codes right before an emissions test to pass temporarily is unethical and often ineffective. The vehicle’s system will likely detect the ongoing issue, and the “Check Engine” light and codes will return soon, potentially failing the test anyway.

- If You Are Unsure of the Code’s Meaning: If you don’t understand why a code appeared, clearing it blindly is not advisable. Proper diagnosis is essential to address the root cause of the problem.

Important Considerations:

- Recurring Codes: If a code reappears shortly after clearing, it indicates a persistent problem that needs proper diagnosis and repair.

- Freeze Frame Data: Before clearing codes, some scanners allow you to view “freeze frame” data. This data captures engine conditions at the moment the code was triggered and can be valuable for diagnosis.

- Professional Advice: If you are unsure about diagnosing or repairing OBD2 code issues, always consult a qualified mechanic.

Clearing OBD2 codes is a tool for use after repairs or in specific situations, but it should never replace proper diagnosis and repair. Always prioritize understanding and fixing the root cause of any OBD2 code.

Preventing OBD2 Codes: Proactive Vehicle Maintenance

Preventing OBD2 codes from appearing in the first place is always better than dealing with them after they arise. Proactive vehicle maintenance is the key to keeping your vehicles running smoothly, efficiently, and code-free. Regular maintenance not only prevents OBD2 codes but also extends the life of your vehicle and saves you money on costly repairs in the long run.

[Picture #5] Regular vehicle maintenance is crucial to prevent OBD2 codes and ensure vehicle longevity.

Here are essential practices for preventing OBD2 codes:

-

Regular Scheduled Maintenance:

- Follow the Maintenance Schedule: Adhere to the maintenance schedule outlined in your vehicle’s owner’s manual. This schedule is designed by the manufacturer and specifies intervals for oil changes, filter replacements, fluid checks, spark plug replacement, timing belt service, and other crucial maintenance tasks.

- Don’t Delay Maintenance: Timely maintenance is crucial. Delaying oil changes, for example, can lead to engine sludge buildup and trigger codes related to oil pressure or engine performance.

- Keep Records: Maintain records of all maintenance performed. This helps track when services are due and can be valuable for resale.

-

Use Quality Fluids and Parts:

- High-Quality Engine Oil: Use the correct type and grade of engine oil recommended for your vehicle. High-quality oil provides better lubrication and protection, reducing engine wear and the likelihood of engine-related codes.

- Genuine or Reputable Parts: When replacing parts, especially critical components like sensors, spark plugs, and filters, use genuine manufacturer parts or reputable aftermarket brands. Inferior parts can fail prematurely or not function correctly, triggering OBD2 codes.

- Proper Coolant and Fluids: Ensure the cooling system is filled with the correct type and concentration of coolant. Use manufacturer-recommended transmission fluid, brake fluid, and power steering fluid.

-

Regular Vehicle Inspections:

- Visual Checks: Regularly inspect your vehicle visually. Check for leaks under the vehicle, examine belts and hoses for wear or cracks, and ensure all lights are working.

- Tire Maintenance: Maintain proper tire pressure and rotate tires regularly. Uneven tire wear can affect sensors related to ABS and traction control.

- Brake System Checks: Have your brakes inspected regularly. Worn brake pads or rotors can trigger ABS or brake system codes.

-

Proper Driving Habits:

- Avoid Harsh Driving: Aggressive driving habits, like rapid acceleration and hard braking, put extra stress on vehicle components and can contribute to premature wear and tear, potentially leading to OBD2 codes over time.

- Warm-Up Engine: In cold weather, allow the engine to warm up briefly before driving to ensure proper lubrication and reduce engine stress.

-

Address Minor Issues Promptly:

- Don’t Ignore Warning Signs: Pay attention to any unusual noises, smells, or changes in vehicle performance. Address minor issues promptly before they escalate into major problems that trigger OBD2 codes.

- Investigate “Check Engine” Light: If the “Check Engine” light illuminates, don’t ignore it. Have the codes read and diagnosed as soon as possible.

-

Fuel System Care:

- Use Quality Fuel: Use gasoline from reputable stations and consider using the octane rating recommended for your vehicle.

- Avoid Running Fuel Tank Low: Regularly running the fuel tank very low can draw sediment into the fuel system and potentially damage the fuel pump or fuel filter, which can trigger codes.

By implementing these proactive maintenance practices, you can significantly reduce the likelihood of OBD2 codes appearing, keep your vehicles in optimal condition, and enjoy more reliable and trouble-free driving.

Managing OBD2 Codes for Fleets: Efficiency and Proactive Maintenance

For fleet managers, handling OBD2 codes efficiently is crucial for minimizing vehicle downtime, controlling maintenance costs, and ensuring smooth fleet operations. Standardizing and automating OBD2 code management can significantly streamline these processes.

Here are effective strategies for managing OBD2 codes in a fleet environment:

-

Centralized OBD2 Code Tracking System:

- Implement a Fleet Management System: Utilize a fleet management system that integrates OBD2 data from all vehicles into a central platform. Systems like CalAmp iOn offer real-time OBD2 code monitoring, vehicle diagnostics, and maintenance scheduling features.

- Real-Time Code Alerts: Set up real-time alerts to notify fleet managers or maintenance personnel immediately when an OBD2 code is triggered in any fleet vehicle.

- Historical Code Data Analysis: Use the centralized system to analyze historical OBD2 code data. Identify trends, recurring issues with specific vehicle models or systems, and patterns that can inform preventative maintenance strategies.

-

Remote OBD2 Code Diagnostics:

- Telematics Integration: Leverage telematics systems that provide remote access to OBD2 data. This allows for initial diagnostics to be performed remotely, without physically inspecting each vehicle.

- Remote Code Reading and Clearing (With Caution): Some advanced telematics systems allow for remote reading and clearing of OBD2 codes. However, clearing codes remotely should be done cautiously and only after proper remote diagnosis or after confirming repairs have been made.

-

Prioritized Maintenance Scheduling Based on Code Severity:

- Code Severity Classification: Establish a system to classify OBD2 codes based on their severity and potential impact on vehicle operation (e.g., high, medium, low severity).

- Prioritized Repair Scheduling: Prioritize repairs based on code severity. High-severity codes that indicate critical safety or operational issues should be addressed immediately. Lower-severity codes can be scheduled for repair during routine maintenance intervals.

-

Integration with Maintenance Workflow:

- Automated Work Orders: Integrate the OBD2 code tracking system with the fleet maintenance workflow. Automatically generate work orders when OBD2 codes are detected, streamlining the repair process.

- Parts Inventory Integration: Connect the system with parts inventory management to ensure necessary parts are readily available for common OBD2 code repairs.

-

Driver Training and Reporting:

- Driver Awareness Training: Educate drivers on the importance of reporting “Check Engine” lights and any vehicle performance issues promptly.

- Driver-Reported Issues: Combine OBD2 data with driver-reported vehicle issues for a more comprehensive understanding of vehicle health.

-

Preventative Maintenance Programs Based on OBD2 Data:

- Data-Driven Preventative Maintenance: Use insights from OBD2 code history to refine preventative maintenance schedules. For example, if certain codes related to spark plugs or air filters are common at specific mileages, adjust maintenance schedules accordingly.

- Proactive Component Replacement: Based on recurring OBD2 code patterns, consider proactive replacement of components before they fail completely, reducing downtime and unexpected breakdowns.

By implementing these fleet-focused OBD2 management strategies, fleet managers can move from reactive repairs to proactive maintenance, optimizing vehicle uptime, reducing costs, and improving overall fleet efficiency.

In Conclusion

OBD2 codes are a vital diagnostic tool built into modern vehicles. Understanding what these codes mean and how to address them is essential for every vehicle owner and especially critical for fleet managers. By learning to read, interpret, and act upon OBD2 codes, you can ensure your vehicles are properly maintained, efficiently repaired, and stay on the road longer.

From understanding the different types of codes and their structure to utilizing OBD2 scanners and implementing proactive maintenance, this guide has equipped you with the knowledge to confidently handle OBD2 codes. For fleets, leveraging centralized tracking and telematics systems enhances these capabilities, enabling efficient management and minimizing downtime. Embrace OBD2 codes as a valuable communication tool from your vehicle, and use this knowledge to keep your vehicles running at their best.

To further enhance your fleet management and vehicle maintenance strategies, consider exploring advanced telematics solutions like CalAmp iOn. These systems provide comprehensive vehicle health monitoring and can significantly streamline OBD2 code management and overall fleet operations. Take control of your vehicle maintenance, understand your OBD2 codes, and drive forward with confidence.