The electrical system in a modern vehicle is its nervous system, orchestrating everything from ignition and fuel delivery to advanced driver-assistance systems (ADAS) and in-car entertainment. This intricate network, composed of the battery, alternator, starter, and a complex web of sensors and wiring, is crucial for a vehicle’s seamless operation. As vehicles become increasingly sophisticated, their electrical systems have evolved to incorporate digital fuel injection, complex infotainment systems, and automated driving technologies, all reliant on precise electrical power and communication.

Alt text: Foxwell OBD2 scanner displaying various diagnostic functions on its color screen, highlighting its utility for automotive electrical problem diagnosis.

Understanding Vehicle Electrical Systems

At the heart of your car’s electrical system is the battery, providing the initial energy to start the engine and power electrical components when the engine is off. Once running, the alternator takes over as the primary power generator, recharging the battery and supplying power to the vehicle’s electrical systems. The starter motor, energized by the battery, cranks the engine to initiate combustion.

Beyond these essentials, Electronic Control Units (ECUs) and a multitude of sensors manage every aspect of vehicle performance. These range from engine timing and airbag deployment to brake system management and climate control, all relying on a healthy electrical system.

The Urgency of Prompt Electrical Issue Diagnosis

Timely diagnosis of electrical problems is paramount for maintaining vehicle reliability and performance. Electrical malfunctions can manifest in various ways, from subtle performance issues to complete breakdowns. For example, a failing alternator can lead to insufficient battery charging, potentially causing unexpected stalling or starting failures.

Neglecting minor electrical issues can also escalate into significant, costly repairs. A seemingly small problem like battery terminal corrosion can increase electrical resistance, causing wires to overheat and raising the risk of electrical fires.

Modern vehicles, with their integrated electronic systems, are particularly susceptible to cascading failures. A fault in one part of the electrical system can trigger malfunctions in seemingly unrelated components. What appears to be an engine problem might, in fact, stem from an electrical system issue.

This is where OBD2 scanners become invaluable. These tools can interface with your vehicle’s computer to read diagnostic codes, offering crucial insights into potential electrical faults. Early detection through OBD2 scanners ensures vehicle efficiency and enhances passenger safety by verifying the proper function of all safety systems. In this guide, we’ll explore how OBD2 scanners are instrumental in diagnosing electrical problems, ensuring the long-term reliability and dependability of modern vehicles.

Key Features of OBD2 Scanners for Electrical Diagnostics

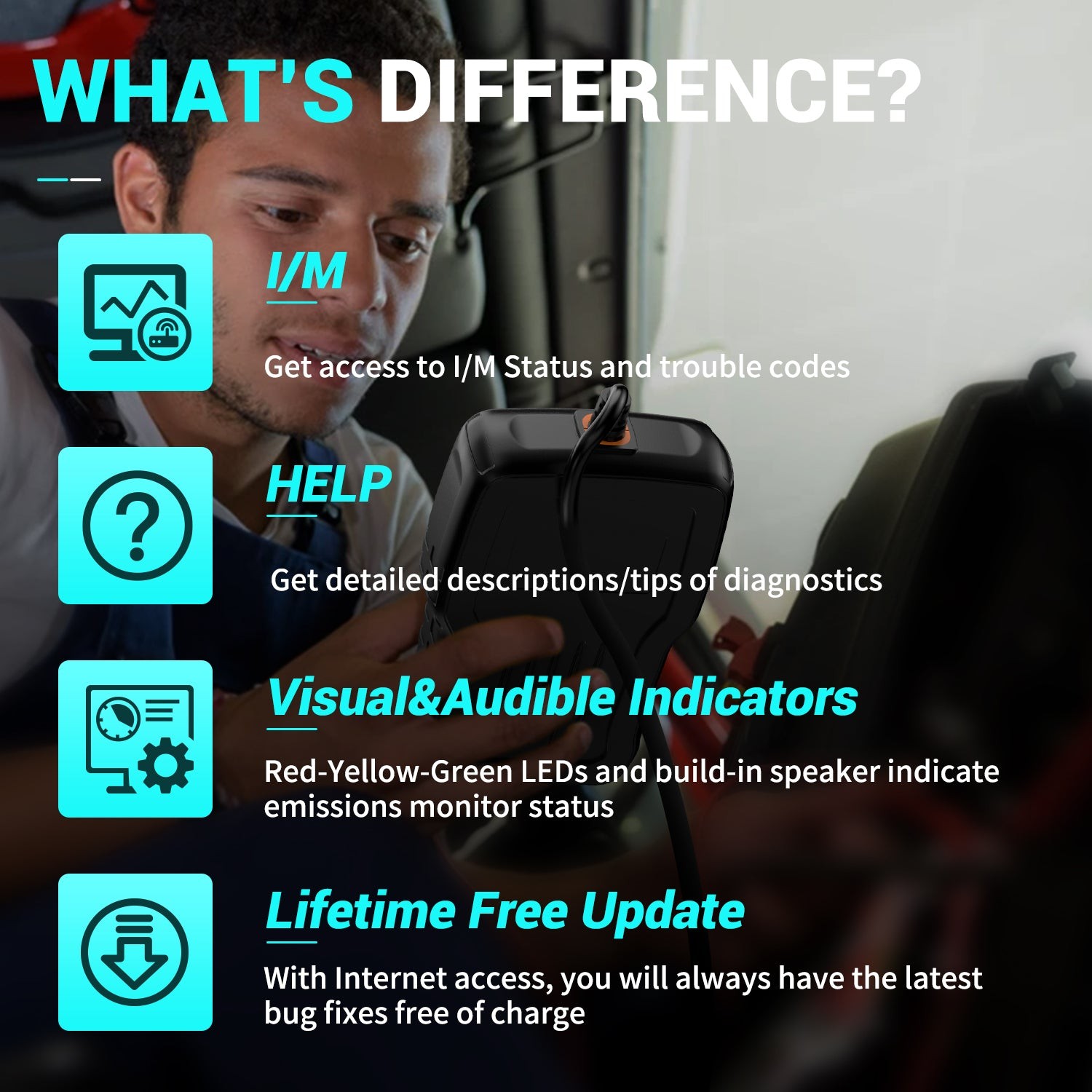

OBD2 scanners are indispensable tools for diagnosing a wide range of automotive issues, especially intricate electrical problems that can compromise vehicle performance and safety. These scanners are equipped with features that make them exceptionally effective in electrical diagnostics. Let’s examine these features and compare the capabilities of two popular Foxwell scanner models: the NT710 and NT809.

Essential Features for Diagnosing Electrical Faults

- Live Data Monitoring: This feature allows technicians and vehicle owners to monitor real-time data from the vehicle’s sensors and electronic systems. By observing parameters like voltage outputs, current draws, and signal frequencies, users can identify anomalies that point to electrical problems.

- Voltage Checks: Many OBD2 scanners can measure and display voltage readings from various vehicle circuits. This is critical for diagnosing battery and alternator issues, such as overcharging or undercharging, which can lead to significant electrical system failures.

- Data Graphing: Advanced scanners can graph live data over time, making it easier to spot intermittent electrical issues or fluctuations that might be missed in a static diagnostic test.

- Circuit Testing: Some scanners offer built-in circuit testing capabilities, allowing direct verification of circuit and component integrity through the scanner interface, providing dynamic diagnostic capabilities.

- System-Specific Tests: These include dedicated tests for critical electrical systems like the charging system, starting system, and battery health, providing in-depth analysis of these vital components.

Model Comparison: Foxwell NT710 vs. NT809

| Feature | Foxwell NT710 | Foxwell NT809 |

|---|---|---|

| Live Data | Yes | Yes, with enhanced graphing capabilities |

| Voltage Checks | Yes | Yes, across more systems |

| Bi-directional Control | Limited | Yes, advanced bi-directional control for component testing and activation |

| Special Functions | Basic resets and service functions | Extensive special functions, including advanced system tests and adaptations |

| User Interface | User-friendly, simpler navigation | Enhanced touchscreen interface, faster processing, more intuitive navigation |

| Professional Use | Ideal for DIYers and some professional tasks | Designed for professional technicians and complex diagnostics |

Comparative Overview:

Both the Foxwell NT710 and NT809 offer robust diagnostic features. However, the NT809 is better suited for comprehensive electrical diagnostics due to its advanced functionalities like bi-directional control, a more intuitive user interface, and faster processing speeds. The NT809’s sophisticated features make it an excellent choice for professionals and those dealing with intricate vehicle electrical systems.

When selecting an OBD2 scanner for electrical diagnostics, consider the features that align with your diagnostic needs. Features such as live data monitoring, voltage checks, and bi-directional control significantly simplify the process of diagnosing and resolving vehicle electrical issues. Whether you are a professional technician or a DIY enthusiast, choosing the right tool, like the Foxwell NT710 or NT809, depends on the complexity of the tasks you typically undertake and the depth of diagnostics required.

Step-by-Step Guide: Diagnosing Electrical Problems with an OBD2 Scanner

Using an OBD2 scanner, such as the Foxwell NT710, can significantly streamline the diagnosis of vehicle electrical problems. This step-by-step guide will walk you through the process of preparing your vehicle and effectively using the scanner to ensure accurate diagnostics and solutions for electrical issues.

Vehicle and Scanner Preparation

Preparing Your Vehicle:

- Safety First: Ensure your vehicle is parked in a safe, level location. Engage the parking brake and turn off the ignition.

- Check Battery Voltage: Reliable electronic diagnostics depend on a stable power supply. Verify that your car battery is adequately charged. A weak battery can lead to inaccurate readings or prevent the scanner from functioning correctly.

Preparing Your Scanner:

- Software Update: Ensure your Foxwell NT710 scanner is updated with the latest software. This ensures compatibility with recent vehicle models and access to the newest features and diagnostic protocols.

- Familiarization: If you are new to the NT710 scanner, take some time to familiarize yourself with its functions. Read the user manual to understand its capabilities and learn how to navigate the menus effectively.

Diagnostic Process: From Connection to Analysis

Connecting the Scanner:

- Locate the OBD2 Port: The OBD2 port is typically located under the dashboard on the driver’s side. It might be near the steering column or above the pedals.

- Establish Connection: Plug the Foxwell NT710 scanner into the OBD2 port, ensuring a secure connection.

Powering Up the Scanner:

- Ignition to “ON”: Turn your vehicle’s ignition to the “ON” position without starting the engine, unless the test you are performing requires the engine to be running.

- Power On Scanner: The NT710 should power on automatically once connected. If not, press the power button on the scanner.

Navigating to the Diagnostic Menu:

- Vehicle Selection: Enter your vehicle’s make, model, and year. This allows the scanner to use the correct diagnostic protocols for your car.

- Access Electrical System Diagnostics: Navigate the scanner’s menus to find electrical system diagnostics. This might be located under “Control Modules,” then “Body Control Module,” or directly under an “Electrical Systems” heading.

Running Diagnostics:

- Retrieve Trouble Codes: Begin by checking for Diagnostic Trouble Codes (DTCs) stored in the vehicle’s computer. The NT710 will display any codes and provide brief descriptions of the issues.

- Monitor Live Data: Access the live data stream to observe real-time readings from electrical components. Monitor voltages, currents, and other relevant data to assess the condition of electrical systems.

Analyzing the Data:

- Interpret Codes and Data: Use the information from the DTCs and live data to pinpoint potential problems. Compare readings against expected values (refer to your vehicle’s service manual for specifications).

- Component-Specific Checks: If the scanner indicates issues with specific components like sensors, switches, or relays, you may need to perform targeted tests such as voltage drop tests, resistance measurements, and continuity checks.

Resolution and Verification:

- Perform Repairs: Based on your diagnosis, perform the necessary repairs or replacements for faulty components or wiring.

- Clear Codes: After completing repairs, use the NT710 to clear the trouble codes from the vehicle’s computer.

- Re-test the System: Rerun the diagnostics to confirm that all electrical issues have been resolved and no new codes are present.

Documentation:

- Record Findings: Keep a detailed log of the diagnostic process, including codes found, repairs made, and results. This documentation is valuable for future maintenance and tracking recurring issues.

By following these steps, you can effectively use the Foxwell NT710 to diagnose and address electrical issues in your vehicle, ensuring it remains in optimal condition and enhancing your understanding of automotive electrical diagnostics.

Alt text: A hand connecting a Foxwell OBD2 scanner cable to a car’s OBD2 port located beneath the dashboard, demonstrating the physical connection process for automotive diagnostics.

Troubleshooting Tips Using OBD2 Data

An OBD2 scanner provides a wealth of information crucial for diagnosing and resolving issues in modern vehicles. Accurate interpretation of this data is key to effective repairs and proactive vehicle maintenance. Here are guidelines for interpreting scanner data and tips for handling common challenges like intermittent faults and error codes.

Interpreting Scanner Data for Effective Troubleshooting

Understanding Diagnostic Trouble Codes (DTCs): OBD2 scanners display DTCs, which are essential for identifying problems. Each code has a specific meaning, indicating potential issues within different vehicle systems. For example, codes starting with ‘P’ typically relate to powertrain issues, such as engine or transmission problems.

Analyzing Live Data Streams: OBD2 scanners can stream real-time data from various sensors, including engine temperature, RPM, oxygen sensor readings, and more. To effectively use this data:

- Compare to Normal Values: Understand the standard operating ranges for each data parameter for your specific vehicle model. This information is usually available in the vehicle’s service manual.

- Identify Outliers: Data points that significantly deviate from normal ranges can clearly indicate a problem area.

Leveraging Freeze Frame Data: Many scanners can capture freeze frame data, which is a snapshot of the vehicle’s condition at the moment a fault code is triggered. This is particularly useful for diagnosing intermittent issues that may not be present during a diagnostic session.

Graphing Data Over Time: Utilize the scanner’s graphing capabilities to plot data over time. This can reveal patterns or anomalies that are not apparent in static data readings, helping to diagnose issues that fluctuate or occur under specific conditions.

Tips for Addressing Common Electrical Issues

Intermittent Faults:

- Check Grounds and Connections: Intermittent faults are often caused by poor electrical connections or grounding issues. Inspect all connectors for looseness, corrosion, or damage. Ensure ground connections are clean and secure.

- Wiring Harness Flex Test: Gently flex wiring harnesses while monitoring live data. This can help identify breaks or shorts in the wiring that only occur when the wires are moved.

- Component Stress Testing: Use the scanner to activate components intermittently while monitoring live data. This can reveal components that fail only under certain operational stresses.

Error Codes:

- Prioritize Multiple Codes: If multiple DTCs are present, address them in the order they appeared. Sometimes, one primary issue can cause a cascade of secondary error codes.

- Consult Repair Resources: Use vehicle-specific service manuals, online forums, and repair databases to understand the common causes and troubleshooting steps for each DTC.

- Clear and Re-scan: After addressing the identified issues, clear the DTCs using the scanner and then re-scan the vehicle to ensure no codes reappear, confirming the repair was successful.

General Best Practices:

- Keep Scanner Software Updated: Regularly update your scanner’s firmware and software to ensure it has the latest features, vehicle coverage, and diagnostic accuracy.

- Regular Sensor Calibration: Components like throttle position sensors may require calibration. Follow manufacturer guidelines to calibrate sensors and other components to prevent inaccurate readings.

- Document Diagnostic Processes: Maintain a detailed record of all diagnostic codes, troubleshooting steps, repairs performed, and outcomes. This history is invaluable for tracking recurring issues and planning preventative maintenance.

Mastering the interpretation of OBD2 scanner data and applying these troubleshooting techniques will empower you to effectively diagnose and repair vehicle problems, minimize downtime, and reduce the likelihood of costly, misdiagnosed repairs. This approach ensures thorough and accurate maintenance, contributing to the longevity and performance of your vehicle.

Conclusion

An effective OBD2 scanner is more than just a code reader; it is a powerful diagnostic tool that, when used correctly, can provide deep insights into your vehicle’s electrical system and overall health. It requires a combination of technical knowledge, careful data analysis, and a systematic approach to troubleshooting that goes beyond simple code clearing.

Each step in the diagnostic process, from initial connection to final verification, is crucial and can be the difference between a temporary fix and a lasting solution. Whether you are troubleshooting a complex electrical issue, addressing engine performance problems, or performing routine maintenance, an OBD2 scanner is an indispensable tool for modern vehicle care.

Integrating an OBD2 scanner into your regular vehicle maintenance routine ensures your vehicle remains a reliable companion, ready to meet the demands of modern driving with confidence.