Understanding your vehicle’s health is becoming increasingly accessible, thanks to On-Board Diagnostics (OBD2) systems. At the heart of this system are OBD2 Parameter IDs, or PIDs. But what exactly are Obd2 Pids, and how can they help you understand your car better? This guide will delve into the world of OBD2 PIDs, explaining their function, how to interpret them, and why they are essential for modern vehicle diagnostics.

OBD2 is essentially your car’s self-diagnostic system. It’s a standardized system present in most vehicles since the mid-1990s, designed to monitor engine and emission control components. When something goes wrong, like an engine misfire or an emission issue, OBD2 throws a Diagnostic Trouble Code (DTC) and often illuminates the Malfunction Indicator Light (MIL), commonly known as the “check engine light.” However, OBD2 is capable of much more than just reporting errors. It provides a wealth of real-time data about your vehicle’s operation, and this is where OBD2 PIDs come into play.

Decoding the Language of Your Car: OBD2 PIDs Explained

OBD2 PIDs are codes used to request data from your vehicle’s computer. Think of them as specific questions you can ask your car. Each PID corresponds to a particular parameter or sensor reading, such as engine speed, coolant temperature, or throttle position. These parameters are standardized by SAE J1979, ensuring a degree of uniformity across different vehicle makes and models.

To access this valuable data, tools like OBD2 scanners or interfaces are used. These devices connect to your car’s OBD2 port, typically located under the dashboard, and communicate with the vehicle’s computer system. The communication happens over the Controller Area Network (CAN) bus, a robust communication network within your car.

The Request and Response Mechanism

Requesting data using OBD2 PIDs involves sending a specific CAN frame to the vehicle. For instance, to request the vehicle speed (PID ‘0D’), an OBD2 tool sends a CAN frame with a specific ID (7DF) and a data payload containing the service code (01 for current data) and the PID (0D).

The vehicle, if it supports the requested PID, responds with another CAN frame. This response frame contains the requested data, along with identifiers to confirm it’s a response to your request. The data itself is typically in hexadecimal format and needs to be decoded to a human-readable physical value.

Let’s look at an example for requesting Vehicle Speed (PID 0D):

| CAN ID | Byte 0 | Byte 1 | Byte 2 | Byte 3 | Byte 4 | Byte 5 | Byte 6 | Byte 7 |

|---|---|---|---|---|---|---|---|---|

| Request | 7DF | 02 | 01 | 0D | AA | AA | AA | AA |

| Response (example) | 7E8 | 03 | 41 | 0D | XX | AA | AA | AA |

In the response example above, ‘XX’ represents the data bytes containing the vehicle speed in hexadecimal format. The ’03’ in Byte 0 indicates the number of data bytes following, ’41’ is the response service ID (0x40 + requested service ID 01), and ‘0D’ confirms the PID being responded to.

From Hexadecimal to Real-World Values: Decoding OBD2 PID Data

The raw data received in the OBD2 response frame is often not directly usable. It’s usually encoded in hexadecimal and needs to be converted to a physical value like kilometers per hour (km/h) or degrees Celsius (°C). This conversion involves applying scale and offset factors defined for each PID.

Consider the Vehicle Speed PID (0D) again. If the response byte ‘XX’ is ’12’ in hexadecimal, we convert it to decimal, which is 18. For many PIDs, the scale and offset are straightforward. For Vehicle Speed, the scale is 1, and the offset is 0. Thus:

Physical value = Offset + (Scale * Raw value in decimal)

Physical value = 0 + (1 * 18) = 18 km/hFor other PIDs, the calculation might be slightly more complex, involving different scale and offset values, and sometimes combining multiple bytes for parameters like engine speed, which often uses two bytes. The OBD2 PID table below provides these crucial scale and offset details.

Navigating the OBD2 PID Table: Your Key to Vehicle Data

A comprehensive OBD2 PID table is invaluable for anyone working with vehicle diagnostics or data logging. These tables list various PIDs along with essential information for decoding them, including:

- PID (Decimal & Hexadecimal): The identifier code for the parameter.

- Name: A descriptive name of the parameter (e.g., Engine Speed, Coolant Temperature).

- Bit Start & Bit Length: Specifies the location and size of the data within the response frame.

- Scale & Offset: The values needed to convert the raw data to a physical unit.

- Min/Max Values: The valid range for the parameter.

- Unit: The physical unit of measurement (e.g., rpm, °C, km/h).

Below is a snippet of a typical OBD2 PID table (Service 01):

| PID dec | PID hex | Name | Bit start | Bit length | Scale | Offset | Min | Max | Unit |

|—|—|—|—|—|—|—|—|—|

| 0 | 00 | PIDs supported [01 – 20] | 31 | 32 | 1 | 0 | Encoded |

| 1 | 01 | Monitor status since DTCs cleared | 31 | 32 | 1 | 0 | Encoded |

| 4 | 04 | Calculated engine load | 31 | 8 | 1/2.55 | 0 | 0 | 100 | % |

| 5 | 05 | Engine coolant temperature | 31 | 8 | 1 | -40 | -40 | 215 | degC |

| 12 | 0C | Engine speed | 31 | 16 | 0.25 | 0 | 0 | 16384 | rpm |

| 13 | 0D | Vehicle speed | 31 | 8 | 1 | 0 | 0 | 255 | km/h |

This table allows you to quickly look up a PID, understand its meaning, and find the necessary information to decode its data. For example, to get Engine Speed (PID 0C), you would refer to this table to find the scale (0.25) and offset (0) needed for conversion.

OBD2 PIDs in Action: Diagnostics and Data Logging

OBD2 PIDs are fundamental for various automotive applications:

- Diagnostics: Mechanics and technicians use OBD2 scanners to read PIDs and diagnose vehicle issues. Unusual PID readings can pinpoint problems with specific sensors or systems.

- Performance Monitoring: Enthusiasts use OBD2 interfaces and data loggers to monitor engine performance in real-time or record data for later analysis. This can be used for tuning, track days, or simply understanding how your car performs under different conditions.

- Telematics and Fleet Management: OBD2 data, accessed via PIDs, is crucial for telematics systems that track vehicle location, driving behavior, and vehicle health for fleet management and insurance purposes.

- DIY Car Repair: For car owners, understanding OBD2 PIDs empowers them to take a more active role in vehicle maintenance and troubleshooting, often saving time and money on repairs.

Programmatic Access to OBD2 PIDs: DBC and CSV Files

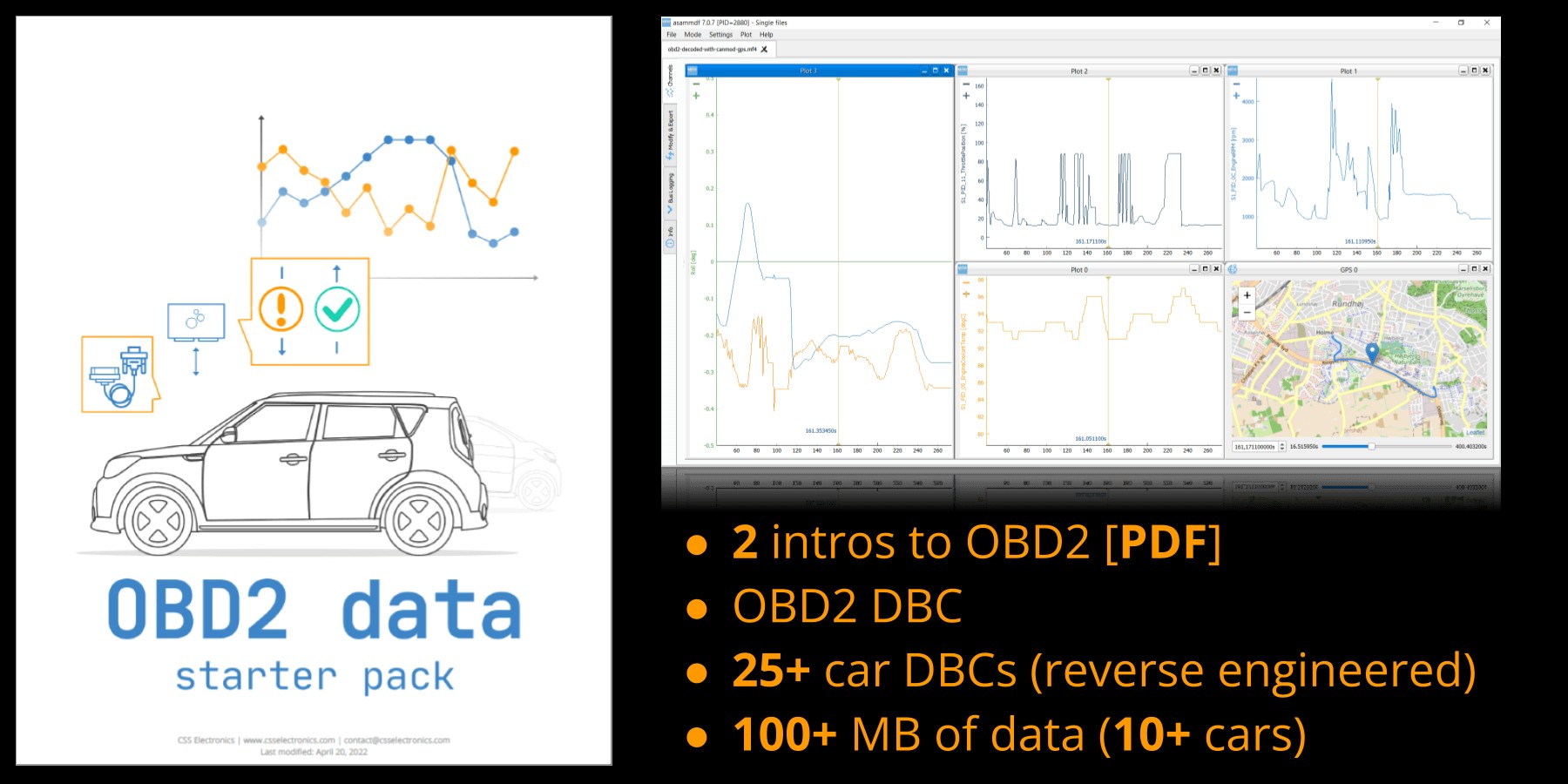

For developers and advanced users who want to programmatically access and decode OBD2 PID data, resources like DBC (CAN database) and CSV files are available.

- DBC Files: A DBC file is a database format that describes the CAN bus communication, including the definitions for OBD2 PIDs. It allows software tools to automatically decode raw CAN data into human-readable parameters using the PID definitions, scale factors, and offsets stored in the file.

- CSV Files: CSV files provide the same information as DBC files but in a simple, comma-separated value format. This is useful for scripting and manual data processing, allowing you to implement custom OBD2 PID decoding in languages like Python or MATLAB.

These programmatic formats streamline the process of working with OBD2 data, especially when dealing with large datasets from data loggers or integrating OBD2 data into custom applications.

{width=1800 height=900}Get Started with OBD2 PIDs

OBD2 PIDs are a powerful tool for anyone interested in understanding and interacting with their vehicle’s data. Whether you are a professional mechanic, a car enthusiast, or a software developer, mastering OBD2 PIDs opens up a world of possibilities for vehicle diagnostics, performance analysis, and data-driven automotive applications. By understanding how to request, decode, and interpret OBD2 PIDs, you gain valuable insights into the inner workings of your car and unlock the potential of on-board diagnostics.

Explore further into the world of OBD2 with these resources:

- OBD2 Explained – A Simple Intro

- OBD2 Data Logger – Record Your Car Data

- Custom Telematics Dashboards using OBD2 Data