For anyone managing a fleet of vehicles or even just a personal car, encountering the term “OBD2 error codes” is quite common. It might sound technical, but it’s essentially your vehicle’s way of communicating potential issues. Think of OBD2 error codes as messages from your car, providing insights into what’s happening under the hood. As someone focused on vehicle maintenance, understanding these codes is invaluable for keeping your vehicles in top shape and minimizing downtime.

In this guide, we’ll break down OBD2 error codes, explaining what they are, how they function, and why they are so important, especially for fleet management. We’ll also explore effective strategies for managing OBD2 error codes, regardless of the size of your fleet.

What Exactly Are OBD2 Error Codes?

On-board diagnostics (OBD-II) error codes are essentially alphanumeric codes generated by your vehicle’s computer system. They act as a communication tool, alerting you to problems detected within your vehicle’s various systems.

Your vehicle is equipped with numerous sensors that constantly monitor different components, from the engine and transmission to the emission system. When these sensors detect an issue or reading outside of the normal parameters, the onboard computer generates a corresponding error code.

These codes can signal a wide range of problems, from minor glitches to more serious malfunctions. For example, the dreaded “Check Engine” light illuminates when the system detects that an engine component or system isn’t performing as expected. This light is your car’s way of saying, “Hey, something needs attention!”

To decipher these messages, you’ll need an OBD2 scanner. This tool plugs into your vehicle’s OBD2 port, typically located beneath the dashboard. Once connected, the scanner reads the error codes, providing a numerical code that helps pinpoint the problem’s source.

This error code acts as a roadmap, guiding you or your mechanic in diagnosing the exact cause of the issue. It’s a powerful resource that aids in effective troubleshooting and informed decision-making, particularly vital for efficient fleet operations.

Types of OBD2 Error Codes: A Quick Breakdown

When an OBD2 error code pops up in one of your fleet vehicles, knowing the type of code is the first step towards understanding the general area of the problem. OBD2 codes are broadly classified into four main categories, each relating to a different vehicle system. Recognizing these categories is crucial for efficient diagnosis and repair.

Powertrain Codes: Engine and Transmission Issues

Powertrain codes, starting with the letter ‘P’, are the most common type of OBD2 error code. They indicate problems within the vehicle’s powertrain, which includes the engine, transmission, and related drivetrain components. These codes provide crucial information about issues affecting your vehicle’s power delivery and overall performance.

For example, the powertrain code P0101 signals a potential issue with the Mass Air Flow (MAF) sensor. The MAF sensor is responsible for measuring the amount of air entering the engine, which is vital for the vehicle’s computer to calculate the correct air-fuel mixture for optimal combustion. A malfunctioning MAF sensor can lead to various problems, including reduced fuel efficiency and decreased engine performance.

Body Codes: Issues with Comfort and Safety Systems

Body codes, starting with the letter ‘B’, point to problems within the vehicle’s body systems. This category includes a wide range of components that contribute to comfort, convenience, and safety, such as lighting, airbags, power windows, and climate control systems.

For example, the body code B0020 indicates a problem within the driver’s side airbag deployment circuit. This is a serious safety concern because if this circuit malfunctions, the driver’s side airbag might not deploy correctly in a collision. Airbags are crucial safety features, and any issue with their operation needs immediate attention.

Chassis Codes: Suspension, Steering, and Braking Problems

Chassis codes, starting with the letter ‘C’, relate to issues within the vehicle’s chassis and its associated systems. This includes critical systems like the suspension, steering, and brakes – all essential for vehicle handling, stability, and safety.

For instance, the chassis code C1234 indicates a problem with the right front wheel speed sensor. A faulty wheel speed sensor can have significant consequences. It can compromise the vehicle’s stability control and handling, making it potentially unsafe to drive, especially in adverse conditions. Furthermore, it can also affect the anti-lock braking system (ABS), leading to reduced braking effectiveness.

Network Communication Codes: Issues with Vehicle Electronics

Network communication codes, starting with the letter ‘U’, signal problems within the vehicle’s communication network. Modern vehicles rely on complex communication networks to allow various modules and sensors to exchange information. These codes indicate disruptions in this communication process.

Take, for example, the network communication code U0100, which signifies a loss of communication with the Engine Control Module (ECM). This issue is often related to electrical problems, such as a faulty battery or wiring issues. When the U0100 code appears, you might experience symptoms like reduced engine power, sluggish acceleration, and poor fuel economy. In severe cases, this communication breakdown could even cause the engine to stall while driving, posing a serious safety hazard.

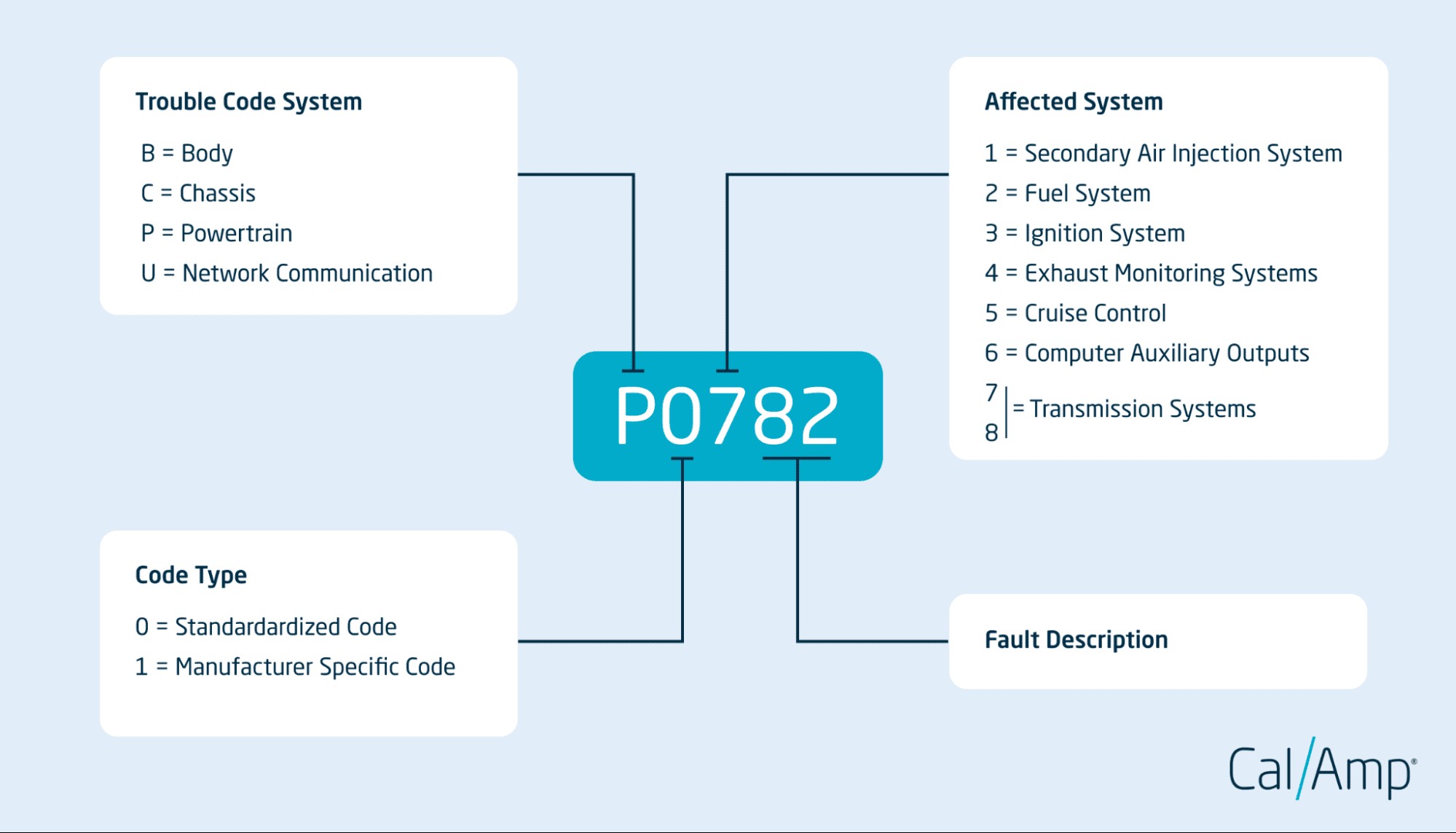

Decoding OBD2 Error Codes: Understanding the Structure

OBD2 error codes aren’t random strings of characters; they follow a specific format. Each code consists of five alphanumeric characters, and each position in the code provides valuable information about the problem. Understanding this structure can make interpreting error codes much easier.

Decoding OBD2 codes structure

Decoding OBD2 codes structure

Let’s break down each part of the five-character OBD2 error code:

1. Trouble Code System: The First Character (Letter)

The first character is always a letter, indicating the primary system where the fault lies.

- P (Powertrain): Relates to the engine, transmission, and drivetrain.

- B (Body): Indicates issues with body-related systems like airbags, lights, and power accessories.

- C (Chassis): Points to problems with chassis systems such as brakes, suspension, and steering.

- U (Network Communication): Signals communication issues between vehicle modules.

2. Code Type: The Second Character (Digit)

The second character is a digit that specifies whether the code is generic or manufacturer-specific.

- 0 (Standardized/Generic): These are common codes defined by SAE standards and are the same across all vehicle makes and models. For example, P0XXX codes are generally generic powertrain codes.

- 1 (Manufacturer-Specific): These codes are defined by the vehicle manufacturer and are specific to a particular make or model. For example, P1XXX codes can be manufacturer-specific powertrain codes.

3. Affected System: The Third Character (Digit)

The third character is a digit that further specifies the subsystem within the broader system indicated by the first character. For powertrain codes (P0XXX and P1XXX), the third digit often represents the following subsystems:

- 1: Fuel and Air Metering: Issues related to fuel mixture, air intake, MAF sensors, etc.

- 2: Fuel and Air Metering (Injector Circuit Malfunction): More specific fuel and air metering problems, often injector related.

- 3: Ignition System or Misfire: Problems with spark plugs, ignition coils, or misfires.

- 4: Auxiliary Emission Controls: Issues with emission control systems like EGR, secondary air injection, catalytic converter.

- 5: Vehicle Speed Controls and Idle Control System: Problems with cruise control, idle speed, etc.

- 6: Computer Output Circuit: Issues with the computer’s output signals to control actuators.

- 7 & 8: Transmission: Problems within the automatic transmission system.

4 & 5. Specific Code: The Last Two Characters (Digits)

The last two characters are digits that provide a highly specific identification of the fault within the identified system and subsystem. For example, in the code P0420, “420” pinpoints a specific issue – in this case, “Catalyst System Efficiency Below Threshold (Bank 1)”. These last two digits are crucial for precise diagnosis.

Clearing OBD2 Error Codes: When and How

While it’s generally recommended to address the underlying problem causing an OBD2 error code rather than simply clearing it, there are situations where clearing codes might be necessary, such as after repairs or for diagnostic purposes. Here are three methods to clear OBD2 error codes:

1. Using an OBD2 Scanner: Direct and Efficient

OBD2 scanners are not just for reading codes; they can also clear them. These devices communicate with your vehicle’s computer to reset the system and turn off the check engine light.

- How it works: Connect the OBD2 scanner to your vehicle’s OBD2 port, navigate to the “Clear Codes” or “Erase Codes” function in the scanner’s menu, and follow the prompts.

- Benefits: OBD2 scanners offer a quick and direct way to clear codes. They are particularly useful after you’ve addressed the issue causing the code. Many scanners also allow you to monitor if the code returns, helping to confirm if the problem is truly resolved.

- Caution: Clearing codes without fixing the underlying problem is only a temporary solution. The code and check engine light will likely reappear if the issue persists.

2. Drive Cycle: Automatic Code Clearing

Some OBD2 error codes, especially those related to emissions, may clear themselves after a series of successful drive cycles. A drive cycle is a specific set of driving conditions that allows the vehicle’s computer to run self-tests and verify that the system is functioning correctly again.

- How it works: The exact drive cycle procedure varies by vehicle manufacturer, but it generally involves a combination of cold starts, highway driving at steady speeds, and city driving. Consult your vehicle’s repair manual or search online for the specific drive cycle for your vehicle make and model.

- Benefits: This method doesn’t require any special tools. If the error was intermittent or related to a minor issue that has resolved itself, the drive cycle might be sufficient to clear the code.

- Limitations: Drive cycles are not effective for all types of codes. More serious or persistent issues will likely require scanner clearing or professional repair. It can also take several drive cycles for a code to clear, and it’s not always guaranteed.

3. Professional Mechanic: Diagnosis and Code Clearing

If you are unsure about the cause of an OBD2 error code, or if the code returns immediately after clearing, it’s best to consult a qualified mechanic. Mechanics have the expertise, experience, and professional-grade diagnostic tools to accurately diagnose the root cause of the problem and perform necessary repairs.

- How it works: A mechanic will use advanced diagnostic equipment to read the OBD2 codes and perform further tests to pinpoint the problem. After completing repairs, they can use their tools to clear the codes and ensure the system is functioning correctly.

- Benefits: Professional diagnosis and repair ensure that the underlying issue is properly addressed, not just masked by clearing the code. Mechanics can also identify related problems that might not be immediately obvious from the OBD2 code alone.

- When to choose this method: Choose this method if you are uncomfortable diagnosing car problems yourself, if the code is persistent or returns quickly, or if you suspect a serious mechanical or electrical issue.

Preventing OBD2 Error Codes: Proactive Vehicle Care

Preventing OBD2 error codes is always better than dealing with them after they appear. Proactive vehicle maintenance and care can significantly reduce the likelihood of encountering error codes and help keep your fleet vehicles running reliably and efficiently.

1. Regular Vehicle Maintenance: The Foundation of Prevention

Regular maintenance is crucial for preventing a wide range of vehicle problems, including those that trigger OBD2 error codes. Following the manufacturer’s recommended maintenance schedule helps catch minor issues before they escalate into major problems.

- Routine Tasks: Regular maintenance includes oil changes, filter replacements (air, oil, fuel, cabin air), fluid checks and top-ups (coolant, brake fluid, power steering fluid, transmission fluid), tire rotations and inspections, brake inspections, spark plug replacements, and timing belt/chain replacements (as needed).

- Following the Schedule: Refer to your vehicle’s owner’s manual for the recommended maintenance schedule. This schedule is usually based on mileage or time intervals, whichever comes first. Adhering to this schedule is key to preventative maintenance.

- Professional Inspections: In addition to routine tasks, consider periodic comprehensive inspections by a qualified mechanic. They can identify potential problems that might be missed during routine maintenance and address them proactively.

2. Using Quality Fuel and Fluids: Protecting Vehicle Systems

Using high-quality fuel and fluids is another essential aspect of preventing OBD2 error codes. Low-quality or incorrect fluids can lead to increased wear and tear on vehicle components and trigger various error codes. Similarly, poor quality fuel can cause incomplete combustion and other engine problems.

- Fuel Quality: Use fuel from reputable gas stations and choose the correct octane rating as recommended by your vehicle manufacturer. Avoid using excessively cheap or low-quality fuel.

- Fluids: Always use fluids that meet or exceed the manufacturer’s specifications for your vehicle. This includes engine oil, transmission fluid, coolant, brake fluid, power steering fluid, and windshield washer fluid. Using the correct fluids ensures proper lubrication, cooling, and system performance.

- Regular Fluid Checks: Periodically check fluid levels and the condition of fluids. Low fluid levels can indicate leaks or excessive consumption, while contaminated or degraded fluids can compromise system performance and lead to damage. Change fluids according to the recommended maintenance schedule.

Managing OBD2 Error Codes for Your Fleet: Streamlining the Process

For fleet managers, dealing with OBD2 error codes across multiple vehicles can be a complex task. Implementing strategies to centralize and streamline OBD2 error code management is crucial for efficiency and minimizing vehicle downtime.

1. Centralized Code Tracking: A Single Point of Information

Centralizing OBD2 error code tracking involves using a system to gather and manage error code data from all fleet vehicles in one central location. This simplifies data access, analysis, and reporting.

- Telematics Solutions: Advanced telematics systems, like CalAmp iOn, offer real-time OBD2 error code monitoring and reporting. These systems automatically collect and transmit error code data to a central platform, providing fleet managers with immediate visibility into vehicle health.

- Benefits of Centralization: Centralized tracking allows for proactive monitoring, faster response times to vehicle issues, trend analysis across the fleet, and improved maintenance scheduling. It eliminates the need for manual code retrieval and data collection, saving time and improving accuracy.

2. Ongoing Fleet Monitoring: Real-Time Alerts and Insights

Implementing ongoing fleet monitoring using telematics systems enables real-time detection of OBD2 error codes and other vehicle performance parameters.

- Real-Time Data: Telematics systems continuously monitor vehicle data, including location, speed, engine parameters, and OBD2 error codes. When an error code is triggered, the system immediately alerts fleet managers.

- Proactive Issue Detection: Real-time monitoring allows for immediate awareness of vehicle problems, enabling prompt action to address issues before they escalate into major breakdowns. This minimizes vehicle downtime and repair costs.

- Performance Monitoring: Telematics systems can also track other performance metrics, such as fuel consumption, driver behavior, and vehicle utilization, providing valuable insights for optimizing fleet operations.

3. Prioritizing Repairs Based on Severity: Efficient Resource Allocation

Not all OBD2 error codes are created equal. Some indicate minor issues, while others signal serious problems that require immediate attention. Prioritizing repairs based on the severity of the error code is essential for efficient resource allocation and minimizing fleet disruption.

- Severity Levels: Categorize error codes based on their potential impact on vehicle safety, operation, and downtime. High-severity codes, such as those related to brakes, airbags, or critical engine malfunctions, should be prioritized for immediate repair.

- Impact Assessment: Evaluate the potential consequences of delaying repair for each error code. Consider factors such as safety risks, potential for further damage, and impact on vehicle availability.

- Scheduled Maintenance for Low-Severity Codes: Lower-severity codes, such as those related to minor sensor issues or non-critical systems, can be scheduled for repair during routine maintenance intervals, optimizing resource utilization.

In Summary: OBD2 Error Codes as Your Vehicle’s Voice

OBD2 error codes are a vital communication tool from your vehicle, providing valuable insights into its health and potential problems. Understanding these codes, their types, and how to interpret them is crucial for effective vehicle maintenance, whether you manage a large fleet or own a single car.

OBD2 scan tools are essential for reading and diagnosing these codes, but for fleet management, comprehensive telematics solutions like CalAmp iOn offer even greater benefits. These systems not only read codes but also provide real-time vehicle performance data, location tracking, and maintenance alerts, empowering fleet managers to proactively maintain their vehicles and minimize downtime.

Request a demo today to discover how CalAmp iOn can revolutionize your fleet management and provide complete visibility into your vehicles’ health and operation.