The check engine light – it’s a sight that can cause any car owner’s heart to skip a beat. But what exactly does it mean when that light illuminates your dashboard? Modern vehicles are equipped with sophisticated onboard diagnostic systems, and thankfully, they’re designed to communicate potential problems through a standardized system known as OBD2 (On-Board Diagnostics II). This system utilizes Diagnostic Trouble Codes (DTCs), often referred to as OBD2 codes, to pinpoint issues within your vehicle. Understanding these codes is the first step in effectively diagnosing and resolving car problems, potentially saving you time and money on unnecessary mechanic visits.

Think of OBD2 codes as your car’s way of telling you what’s wrong. When your car’s computer, the Engine Control Unit (ECU), detects a malfunction in any of its monitored systems, it stores a specific DTC in its memory. By using an OBD2 scanner, a relatively inexpensive and user-friendly tool, you can access these stored codes and begin to understand the nature of the problem.

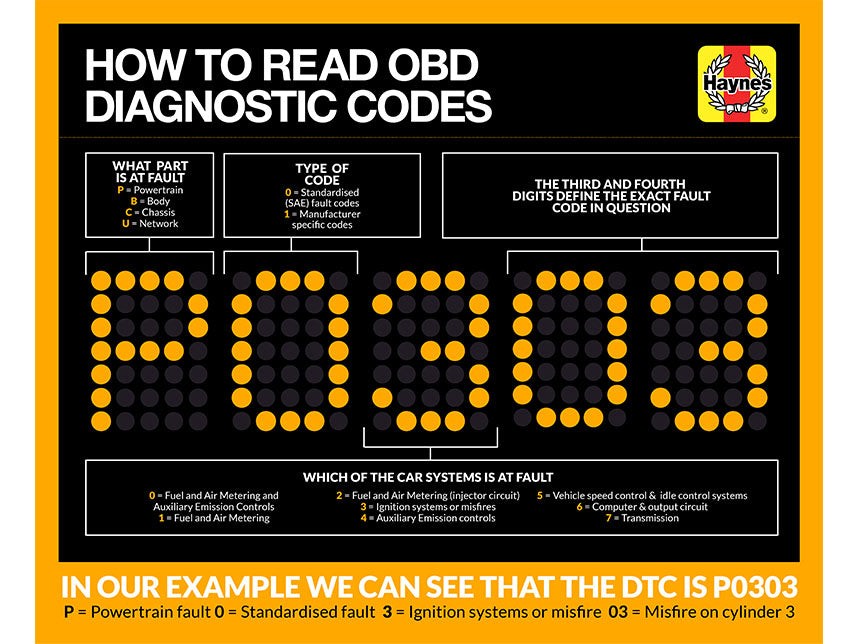

Breaking Down the OBD2 Code Structure

OBD2 codes aren’t random strings of characters; they follow a structured format that provides valuable information about the fault even before you consult a detailed code chart. Let’s dissect the anatomy of a typical OBD2 code, such as P0303, to understand how to interpret its meaning.

The First Character: System Identification

The very first character in an OBD2 code is a letter, and this letter designates the primary system of the vehicle where the fault has been detected. Here’s a breakdown of what each letter signifies:

- P (Powertrain): This is the most common first letter and indicates an issue within the powertrain system. The powertrain encompasses components related to the engine, transmission, and related drivetrain systems. Codes starting with ‘P’ are often related to engine performance, emissions, and transmission problems.

- B (Body): ‘B’ codes point to problems within the vehicle’s body systems. This can include components like power windows, air conditioning, airbags, central locking, and other comfort and convenience features.

- C (Chassis): Codes beginning with ‘C’ relate to the chassis system. This involves systems like braking (ABS), steering, and suspension.

- U (Network/Communication): ‘U’ codes indicate communication issues within the vehicle’s computer network. Modern cars have complex networks connecting various electronic control units. ‘U’ codes can signal problems with data transfer between these systems.

The First Number: Code Type

The first number immediately following the letter provides further categorization of the code:

- 0 (Standardized/Generic): A ‘0’ in this position indicates a standardized or generic OBD2 code. These codes are defined by the Society of Automotive Engineers (SAE) and are common across all makes and models of vehicles that comply with OBD2 standards. This means a P0xxx code will generally have the same meaning regardless of whether you drive a Ford, Toyota, or BMW.

- 1 (Manufacturer-Specific/Enhanced): A ‘1’ in this position signifies a manufacturer-specific or enhanced code. While manufacturers must adhere to the generic OBD2 codes, they can also add their own proprietary codes to provide more detailed diagnostics for their specific vehicles. A P1xxx code, for example, might indicate a more specific issue that is unique to a particular car brand or model.

The Second Number: Subsystem Identification

The second number in the numeric sequence further refines the area of the fault within the identified system. For ‘P’ (Powertrain) codes, these numbers represent different subsystems:

- 0: Fuel and Air Metering and Auxiliary Emission Controls: This category includes issues related to sensors and components that manage the fuel-air mixture and assist in reducing emissions.

- 1: Fuel and Air Metering: This narrows down the focus specifically to problems with the fuel and air metering system, excluding auxiliary emission controls.

- 2: Fuel and Air Metering (Injector Circuit): This is even more specific, pointing to faults within the fuel injector circuits.

- 3: Ignition System or Misfires: Codes in this category are related to the ignition system, including spark plugs, ignition coils, and, crucially, engine misfires.

- 4: Auxiliary Emission Controls: This category focuses on problems within specific emission control components beyond the basic fuel-air mixture.

- 5: Vehicle Speed Control & Idle Control Systems: This covers issues affecting the vehicle’s speed control (like cruise control) and the engine’s idle speed.

- 6: Computer & Output Circuit: This category relates to problems within the ECU itself or its output circuits that control various actuators.

- 7: Transmission: For ‘P’ codes, this signifies problems specifically within the automatic transmission system.

The Third and Fourth Numbers: Specific Fault Code

The final two digits, the third and fourth numbers, are the most specific part of the OBD2 code. They pinpoint the exact nature of the fault within the subsystem identified by the preceding characters and numbers. These numbers are sequential and unique to each specific problem.

Example: Decoding P0303

Let’s revisit our example code: P0303. Using the breakdown we’ve just learned, we can decipher it as follows:

- P: Powertrain – The problem is within the engine or transmission system.

- 0: Standardized Code – This is a generic OBD2 code, common across vehicles.

- 3: Ignition System or Misfires – The fault lies within the ignition system, specifically related to misfires.

- 03: Cylinder 3 Misfire Detected – The final ’03’ specifies that the misfire is occurring in cylinder number 3.

Therefore, P0303 clearly indicates a Powertrain, Standardized code related to Ignition System Misfires, specifically a Cylinder 3 Misfire.

What are… Diagnostic Trouble Codes

What are… Diagnostic Trouble Codes

Understanding Diagnostic Trouble Codes for Automotive Repair

Common OBD2 Code Categories

While the table in the original article provides a list of specific P0xxx codes, it’s helpful to understand the broader categories they fall into. Many common OBD2 codes you might encounter relate to:

- Mass Air Flow (MAF) Sensor Issues (P0100-P0104): These codes often indicate problems with the MAF sensor, which measures the amount of air entering the engine. A faulty MAF sensor can cause various engine performance issues.

- Manifold Absolute Pressure (MAP) Sensor Problems (P0105-P0109): MAP sensors measure manifold pressure, crucial for fuel delivery calculations. Faulty MAP sensors can lead to incorrect fuel mixtures and performance problems.

- Temperature Sensor Circuit Issues (P0110-P0120): This category covers Intake Air Temperature (IAT) and Engine Coolant Temperature (ECT) sensor problems. These sensors are vital for engine management and temperature regulation.

- Throttle Position Sensor (TPS) Problems (P0120-P0129): TPS sensors monitor the throttle valve position, essential for controlling engine power. Issues here can affect acceleration and idle.

- Oxygen Sensor Circuit Malfunctions (P0130-P0167): Oxygen sensors monitor the oxygen content in the exhaust, crucial for emissions control and fuel efficiency. These are very common codes, often related to sensor failure or exhaust leaks.

- System Too Lean/Too Rich (P0170-P0175): These codes indicate that the engine is running with an improper air-fuel mixture, either too lean (too much air) or too rich (too much fuel). These can stem from various issues, including vacuum leaks, fuel delivery problems, or sensor malfunctions.

- Engine Misfire Detected (P0300-P0309): As seen with P0303, these codes pinpoint engine misfires, which occur when combustion is incomplete or absent in one or more cylinders. Misfires can cause rough running, reduced power, and potential engine damage.

- Evaporative Emission Control System (EVAP) Problems (P0440-P0457): EVAP system codes relate to the system that prevents fuel vapors from escaping into the atmosphere. These codes often indicate leaks in the EVAP system.

Utilizing OBD2 Scanners for Diagnosis

To access these valuable OBD2 codes, you’ll need an OBD2 scanner. These scanners range from basic, handheld units to more advanced, professional-grade tools. Using a scanner is typically straightforward:

- Locate the OBD2 Port: The OBD2 port is usually located under the dashboard on the driver’s side of your vehicle. Consult your car’s owner’s manual if you’re unsure of its exact location.

- Plug in the Scanner: With the ignition turned off, plug the OBD2 scanner into the port.

- Turn Ignition to “ON” (Engine Off): Turn the ignition key to the “ON” position without starting the engine. This provides power to the car’s computer and the scanner.

- Read Codes: Follow the scanner’s instructions to read the stored DTCs. The scanner will display the codes, and often provide a brief description.

- Research Codes: Note down the codes and use resources like online OBD2 code databases or repair manuals to get detailed information about their meanings and potential causes.

- Clear Codes (Optional and with Caution): Some scanners allow you to clear codes. However, clear codes only after you have diagnosed and repaired the underlying issue. Clearing codes without fixing the problem will only temporarily turn off the check engine light, and the code will likely return.

Understanding OBD2 codes and their meanings empowers you to be a more informed car owner. While OBD2 codes provide a starting point for diagnosis, remember that they are indicators, not definitive diagnoses. Further investigation and testing may be required to pinpoint the root cause of the problem and perform effective repairs. However, armed with the knowledge of OBD2 codes, you can confidently approach car maintenance and repair, and communicate effectively with mechanics when professional help is needed.