If you’re managing a fleet of vehicles, understanding OBD2 codes is crucial. These codes are essentially your vehicles communicating potential issues, allowing you to proactively manage maintenance and prevent costly breakdowns. As a fleet manager, mastering how to handle OBD2 codes can significantly improve vehicle uptime, reduce repair costs, and enhance the overall efficiency of your operations.

This guide will delve into the world of OBD2 codes, explaining what they are, how to interpret them, and most importantly, how to effectively handle them for your fleet. We’ll cover everything from understanding the different types of codes to implementing strategies for proactive management.

Decoding OBD2 Codes: What Are They?

On-board diagnostics II (OBD2) codes are standardized alphanumeric codes used to report vehicle system malfunctions. Think of your vehicle as having its own internal monitoring system that constantly checks various components and systems, from the engine and transmission to emissions and braking. When this system detects a problem outside of normal parameters, it generates an OBD2 code.

These codes are your vehicle’s way of signaling that something needs attention. The “Check Engine Light” (or Malfunction Indicator Lamp – MIL) on your dashboard illuminates when an OBD2 code is triggered, acting as a visual alert. To understand the specific issue, you need to retrieve the code using an OBD2 scanner. This device plugs into your vehicle’s OBD2 port, usually located under the dashboard, and reads the stored codes.

The retrieved code is a valuable piece of diagnostic information. It doesn’t pinpoint the exact failed part, but it directs you or your mechanic to the area of the problem. Effectively handling OBD2 codes starts with understanding that they are the first step in diagnosing and resolving vehicle issues, ultimately contributing to smoother fleet operations.

Understanding the Different Types of OBD2 Codes

When dealing with OBD2 codes in your fleet, it’s essential to recognize that not all codes are created equal. They are categorized into four main types, each relating to a different area of the vehicle. Knowing these categories helps you quickly understand the general nature of the problem and prioritize your response.

Powertrain Codes (P-Codes)

Powertrain codes, starting with the letter “P,” are the most common type and relate to issues within the engine, transmission, and related drivetrain components. These codes are critical as they often affect the vehicle’s performance and fuel efficiency.

For instance, a P0300 code indicates a “Random/Multiple Cylinder Misfire Detected.” This could stem from various issues like faulty spark plugs, ignition coils, or fuel injectors. Addressing powertrain codes promptly is vital for maintaining vehicle performance and preventing more serious engine damage and ensuring optimal fuel efficiency.

Body Codes (B-Codes)

Body codes, beginning with “B,” indicate problems within the vehicle’s body systems. This includes components like airbags, power windows, seats, lighting, and climate control systems. While body codes might not always directly impact the vehicle’s drivability, some, like airbag system codes, are critical for safety.

A B0001 code, for example, could indicate a problem with the Supplemental Restraint System (SRS), specifically the airbags. Ignoring body codes related to safety systems can have serious consequences in the event of an accident.

Chassis Codes (C-Codes)

Chassis codes, starting with “C,” relate to issues with the vehicle’s chassis systems, including braking, steering, suspension, and ABS (Anti-lock Braking System). These codes are particularly important for safety and handling.

For example, a C0051 code might point to a problem with the brake pressure sensor. Issues in the chassis system can significantly impact vehicle safety and control, making it crucial to address these codes promptly to prevent accidents and ensure driver safety.

Network Communication Codes (U-Codes)

Network communication codes, beginning with “U,” indicate problems in the vehicle’s communication network. Modern vehicles rely on complex networks to allow different modules (like the engine control module, transmission control module, etc.) to communicate with each other. U-codes signal disruptions in this communication.

A common example is a U0100 code, indicating “Lost Communication With ECM/PCM.” This means the engine control module (ECM) or powertrain control module (PCM) is not communicating properly with other modules. Network communication issues can be complex and may affect multiple vehicle systems, often requiring professional diagnostics to resolve.

What OBD2 codes mean

What OBD2 codes mean

Reading and Interpreting OBD2 Codes

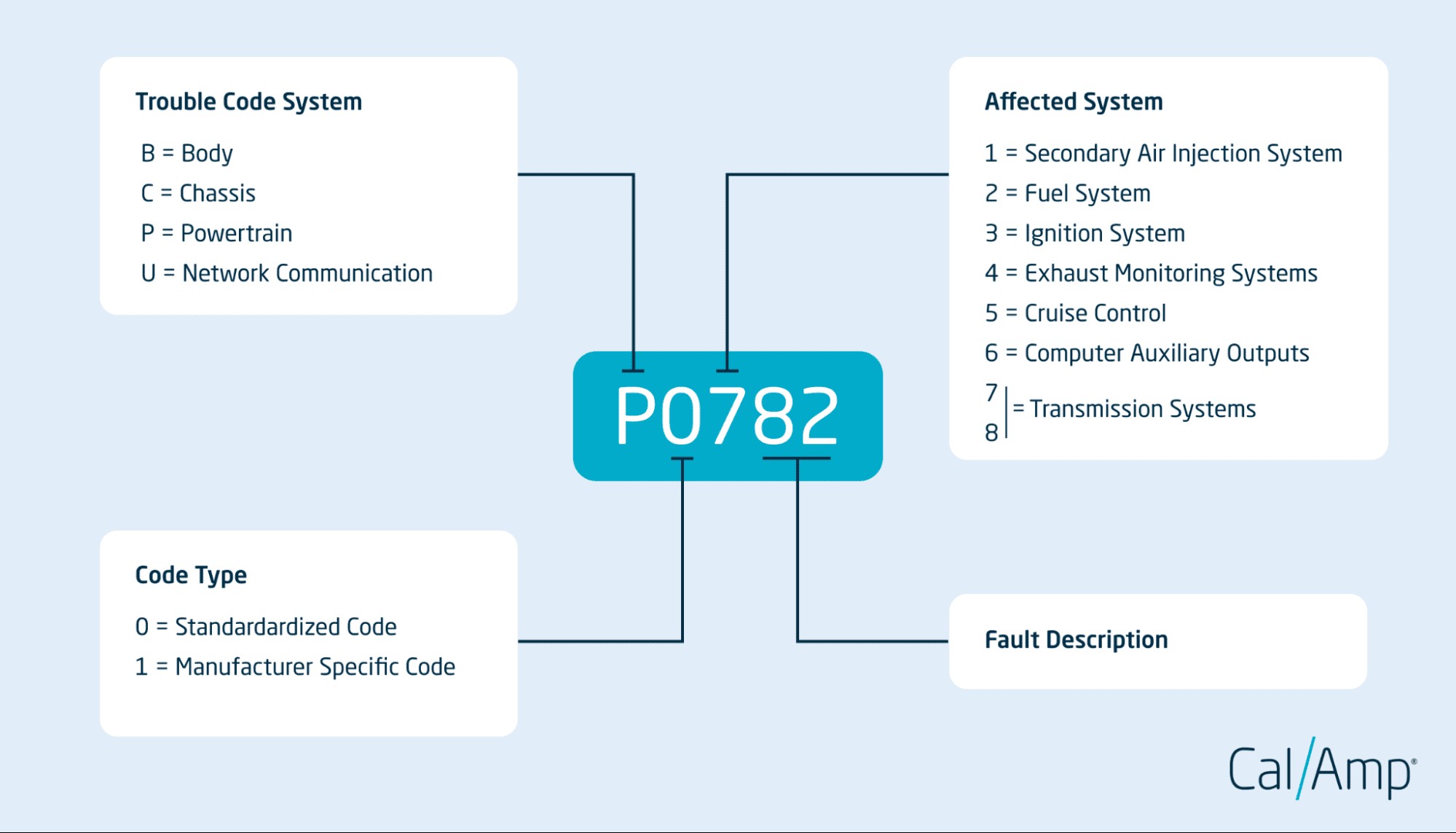

OBD2 codes are structured in a specific five-character format. Understanding this structure is key to interpreting the codes effectively. Each character provides crucial information about the nature and location of the problem.

-

First Character (Letter): Indicates the system affected:

- P – Powertrain (Engine, Transmission)

- B – Body (Airbags, Accessories)

- C – Chassis (Brakes, Steering, Suspension)

- U – Network Communication

-

Second Character (Digit): Indicates code type:

- 0 – Generic (SAE standardized) – Common across all makes and models.

- 1 – Manufacturer Specific – Unique to a particular vehicle manufacturer, providing more detailed information.

-

Third Character (Digit): Indicates the subsystem affected. The common subsystems are:

- 1 – Fuel and Air Metering

- 2 – Fuel and Air Metering (Injector Circuit)

- 3 – Ignition System or Misfire

- 4 – Auxiliary Emission Controls

- 5 – Vehicle Speed Controls and Idle Control System

- 6 – Computer Output Circuit

- 7 & 8 – Transmission

-

Fourth and Fifth Characters (Digits): These two digits are specific and indicate the particular fault within the identified system and subsystem. For example, in P0420, “20” specifies the “Catalyst System Efficiency Below Threshold (Bank 1).”

By breaking down the code character by character, you can gain a good initial understanding of the problem area. Generic codes (second character ‘0’) are a good starting point, while manufacturer-specific codes (second character ‘1’) often require access to manufacturer-specific resources for detailed interpretation.

Handling OBD2 Codes: Reading, Clearing, and Diagnosis

Effectively handling OBD2 codes involves several steps, from reading and understanding the codes to deciding on the appropriate course of action.

Reading OBD2 Codes

The first step is to read the OBD2 code using a scanner. OBD2 scanners range from basic handheld devices to more advanced professional-grade tools.

- Basic Scanners: Affordable and easy to use, these scanners read and clear codes. Suitable for quick checks and basic diagnostics.

- Advanced Scanners: Offer more features, such as live data streaming, graphing, and in-depth diagnostics. These are beneficial for more complex issues and professional use.

- Smartphone Apps & Adapters: Combine an OBD2 adapter that plugs into the vehicle with a smartphone app to read codes and access diagnostic data.

Once connected to the OBD2 port and powered on, the scanner will typically have an option to “Read Codes.” This will display any stored diagnostic trouble codes (DTCs). Record these codes for further investigation.

Clearing OBD2 Codes

Clearing codes should be done with caution. It’s generally not recommended to clear codes without understanding and addressing the underlying issue. Clearing a code simply turns off the Check Engine Light, but the problem might still exist.

However, there are situations where clearing a code might be necessary after a repair or for diagnostic purposes. OBD2 scanners usually have a “Clear Codes” or “Erase Codes” function.

Methods to Clear Codes (with Caution):

- Using an OBD2 Scanner: The most direct method. Follow the scanner’s instructions to clear codes.

- Drive Cycle: Some codes may clear automatically after the vehicle completes a successful “drive cycle” where the system re-tests and confirms the issue is resolved. This is not reliable for all codes and can take time.

- Disconnecting the Battery (Not Recommended): While disconnecting the negative battery terminal can sometimes clear codes, it’s not a reliable or recommended method. It can also reset other vehicle systems and is generally not advisable for modern vehicles.

When to Clear Codes Responsibly:

- After Repair: Once a confirmed issue is properly repaired, clearing the code and then verifying it doesn’t return is a good practice.

- Diagnostic Purposes: To see if a code returns after a specific test or repair attempt.

Important Note: If the Check Engine Light and the OBD2 code reappear shortly after clearing, it indicates the underlying problem persists and requires further diagnosis and repair.

Diagnosing OBD2 Codes

An OBD2 code is a starting point for diagnosis, not the final answer. Effective handling of OBD2 codes requires proper diagnosis to identify the root cause.

Steps for Diagnosis:

- Research the Code: Use online resources, repair manuals, or professional databases to understand the possible causes associated with the specific OBD2 code.

- Visual Inspection: Inspect the related components and systems for obvious signs of damage, leaks, loose connections, or wear.

- Component Testing: Use diagnostic tools (multimeter, scan tool functions) to test sensors, actuators, and circuits related to the code.

- Systematic Troubleshooting: Follow a logical troubleshooting process, often guided by repair information for the specific code and vehicle.

- Professional Help: For complex issues or if you lack the expertise or tools, consult a qualified mechanic or technician for professional diagnosis and repair.

Preventing OBD2 Codes: Proactive Fleet Maintenance

Prevention is always better (and cheaper) than cure. Implementing a proactive maintenance strategy is the most effective way to minimize OBD2 codes and keep your fleet running smoothly.

[Picture #5]

Regular Vehicle Maintenance

Regularly scheduled maintenance is paramount. Following the manufacturer’s recommended maintenance schedule is crucial for preventing many common issues that trigger OBD2 codes.

Key Maintenance Tasks:

- Oil Changes: Regular oil changes with quality oil are essential for engine lubrication and preventing wear.

- Fluid Checks and Changes: Regularly check and replace fluids like coolant, transmission fluid, brake fluid, and power steering fluid according to schedule.

- Filter Replacements: Replace air filters and fuel filters to ensure clean air and fuel delivery to the engine.

- Spark Plug and Ignition System Maintenance: Inspect and replace spark plugs and other ignition components at recommended intervals.

- Brake System Inspections: Regularly inspect brake pads, rotors, lines, and fluid to ensure proper braking performance.

- Tire Rotations and Inspections: Rotate tires regularly and check tire pressure and condition.

- Exhaust System Inspections: Inspect the exhaust system for leaks or damage.

Adhering to Schedules: Refer to the vehicle’s owner’s manual for the manufacturer’s recommended maintenance schedule. Track maintenance intervals for each vehicle in your fleet.

Using Quality Fuel and Fluids

Using high-quality fuel and fluids is another critical preventative measure. Inferior fuels and fluids can lead to various problems that trigger OBD2 codes.

- Fuel Quality: Use fuel from reputable stations and adhere to the vehicle’s recommended octane rating. Avoid low-quality or contaminated fuel.

- Fluids Quality: Use manufacturer-recommended or equivalent quality fluids (engine oil, transmission fluid, coolant, brake fluid). Low-quality fluids can degrade faster and not provide adequate protection.

Efficiently Handling OBD2 Codes for Your Fleet

For fleet managers, handling OBD2 codes efficiently across multiple vehicles requires a systematic approach. Standardization and automation are key to streamlining the process.

Centralized OBD2 Code Tracking

Implement a system to centrally track OBD2 codes for all fleet vehicles. This could be a spreadsheet, database, or a dedicated fleet management software.

Benefits of Centralized Tracking:

- Data Visibility: Provides a clear overview of OBD2 code occurrences across the fleet.

- Trend Identification: Helps identify recurring codes or issues with specific vehicle types or systems, allowing for proactive maintenance adjustments.

- Maintenance History: Creates a historical record of OBD2 codes and repairs for each vehicle.

- Reporting and Analysis: Enables reporting on OBD2 code frequency, repair costs, and vehicle downtime related to diagnostic codes.

Fleet management systems like CalAmp iOn can automate this process, providing real-time OBD2 code data and integration with maintenance scheduling.

Ongoing Fleet Monitoring with Telematics

Utilize telematics systems for real-time vehicle monitoring. Telematics can provide instant alerts when OBD2 codes are triggered, along with other vehicle performance data.

Telematics Benefits for OBD2 Management:

- Real-time Alerts: Immediate notification of new OBD2 codes.

- Remote Diagnostics: Some telematics systems offer remote code reading and basic diagnostic information.

- Proactive Maintenance Scheduling: Integrate OBD2 code alerts with maintenance scheduling systems to trigger timely repairs.

- Reduced Downtime: Faster detection and response to OBD2 codes minimize vehicle downtime.

Prioritizing Repairs Based on Severity

Develop a system for prioritizing repairs based on the severity of the OBD2 codes. Not all codes require immediate attention, but some can indicate critical issues.

Severity-Based Prioritization:

- High Severity Codes: Codes related to safety-critical systems (brakes, airbags, steering), major engine or transmission issues, or codes causing significant drivability problems should be prioritized for immediate repair.

- Medium Severity Codes: Codes indicating potential issues that could worsen over time or affect performance (e.g., emissions codes, sensor malfunctions) should be scheduled for repair soon.

- Low Severity Codes: Codes for minor issues or those with minimal immediate impact (e.g., some body codes, minor sensor readings) can be addressed during routine maintenance intervals.

Prioritization ensures that critical repairs are addressed promptly, minimizing downtime and safety risks, while less urgent issues are managed efficiently.

In Summary: Mastering OBD2 Codes for Fleet Efficiency

Handling OBD2 codes effectively is a cornerstone of proactive fleet management. By understanding what these codes mean, how to interpret them, and implementing strategies for prevention and efficient handling, you can significantly improve your fleet’s performance and reduce operational costs.

From regular maintenance and quality inputs to centralized tracking and telematics monitoring, a comprehensive approach to OBD2 codes empowers fleet managers to stay ahead of potential issues, ensure vehicle uptime, and maintain a safe and efficient fleet. Tools like OBD2 scanners and fleet management systems are invaluable resources in this endeavor. Embrace a proactive approach to OBD2 codes, and you’ll be well on your way to optimizing your fleet operations.

Request a demo today to discover how advanced fleet management solutions can further streamline your OBD2 code handling and overall fleet maintenance.