Gone are the days when deciphering car troubles meant a trip to an expensive mechanic or fumbling with complicated tools. Today, an OBD2 scanner empowers you to take charge of your car’s health right from your garage. These handy devices are not just for reading engine codes; they can also provide valuable insights into your car’s electrical system, including assessing battery health. Understanding Does Obd2 Read Battery information and how to use it can save you from unexpected breakdowns and costly repairs.

This guide will delve into how an OBD2 scanner can be your ally in maintaining a healthy car electrical system, focusing specifically on battery health checks and detecting electrical shorts. By learning to utilize your OBD2 scanner effectively, you can proactively manage your vehicle’s electrical well-being.

Understanding OBD2 Scanners and Battery Diagnostics

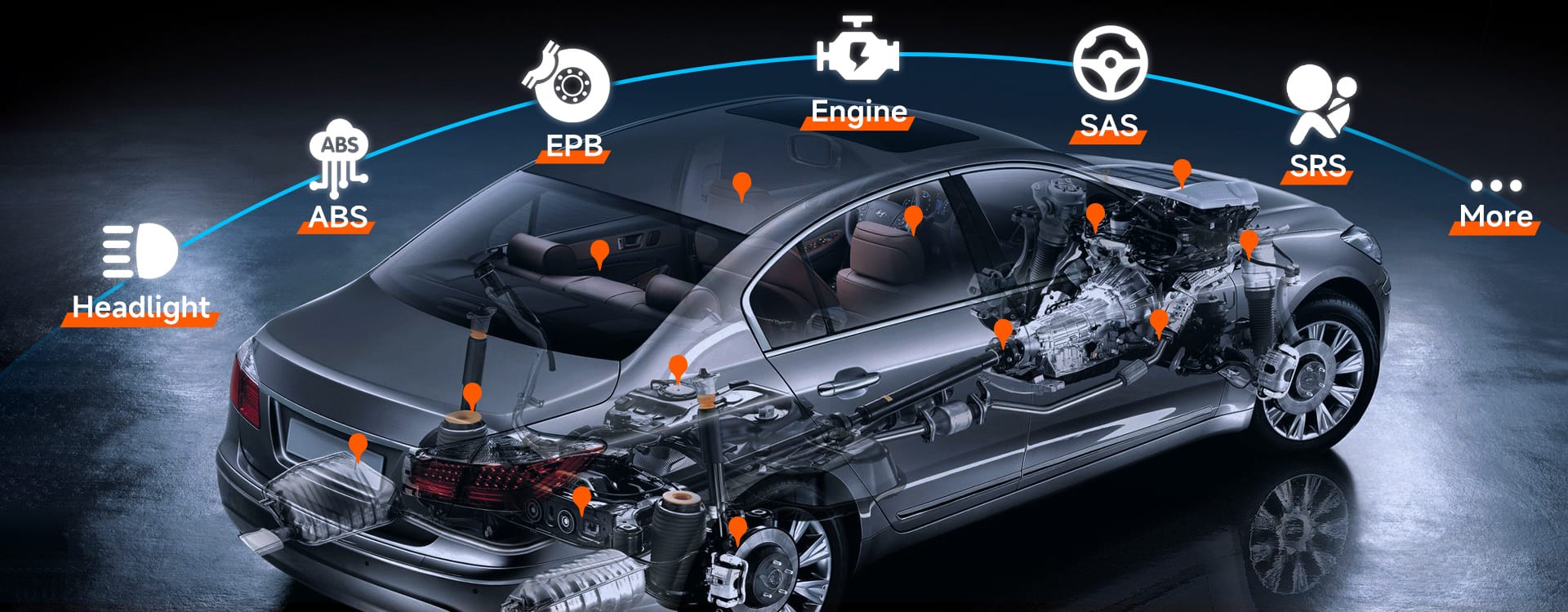

The On-Board Diagnostics II (OBD2) system is a standardized system in most modern vehicles that monitors various aspects of the car’s performance and health. An OBD2 scanner plugs into your car’s diagnostic port, typically located under the dashboard, and retrieves data from the car’s computer. While primarily known for reading engine-related fault codes, many OBD2 scanners offer capabilities that extend to the electrical system, including battery diagnostics.

So, does OBD2 read battery health? The answer is yes, to a significant extent. While not every basic OBD2 scanner provides in-depth battery analysis, many mid-range and advanced scanners can read crucial battery parameters. These parameters often include:

- Battery Voltage: This is the most fundamental reading, indicating the current charge level of your battery. A healthy battery at rest should read around 12.6 volts.

- State of Charge (SOC): Expressed as a percentage, SOC indicates how much charge is currently stored in the battery relative to its full capacity.

- State of Health (SOH): This is a more complex metric that estimates the battery’s overall health and remaining lifespan compared to a new battery.

- Cold Cranking Amps (CCA): CCA measures the battery’s ability to start the car in cold temperatures. An OBD2 scanner might not directly measure CCA, but it can assess voltage drop during cranking, which is related to CCA performance.

Using an OBD2 scanner for battery checks offers several benefits:

- Early Problem Detection: Regular battery checks can identify signs of degradation before failure, preventing unexpected breakdowns.

- Proactive Maintenance: Knowing your battery’s health allows you to plan for replacement proactively, avoiding inconvenient situations.

- Cost Savings: Identifying battery issues early can prevent them from affecting other electrical components, saving on potentially larger repair bills.

- Convenience: Checking your battery with an OBD2 scanner is quick and easy, done from the comfort of your garage.

Step-by-Step Guide: Checking Battery Health with an OBD2 Scanner

While specific steps may vary depending on your OBD2 scanner model, the general process for checking battery health is quite similar. Let’s outline a step-by-step guide, taking the Foxwell BT705, as mentioned in the original article, as a practical example. However, these principles apply broadly to OBD2 scanners with battery testing features.

-

Connect Your OBD2 Scanner: Locate your vehicle’s OBD2 port. It’s usually under the dashboard on the driver’s side. Plug in your OBD2 scanner securely. Some scanners, like the Foxwell BT705, may connect directly to the battery terminals for more comprehensive battery-specific tests, in addition to the OBD2 port connection for system-wide diagnostics. For basic battery voltage checks via the OBD2 port, ensure your car’s ignition is turned to the “ON” position, but the engine is OFF.

-

Navigate to Battery Test/Voltage Reading: Once connected and powered on, navigate the scanner’s menu. Look for options like “Battery Test,” “Voltage,” “System Voltage,” or “Electrical System.” The terminology may differ between scanners.

-

Select Battery Type (If Applicable): Some advanced scanners, particularly those like the BT705 designed for battery analysis, might ask you to select the battery type (AGM, GEL, Flooded, etc.). Choosing the correct type ensures more accurate readings.

-

Initiate Battery Test/Read Voltage: Follow the scanner’s prompts to start the battery test or simply read the voltage. For a basic voltage reading, the scanner will display the current battery voltage. For a comprehensive battery test, the scanner may analyze various parameters and provide readings for SOH, SOC, and voltage.

-

Review the Readings: Once the test is complete, review the displayed readings.

- Voltage: A healthy battery at rest should read approximately 12.6V. Readings below 12.4V may indicate a discharged or weakening battery. Below 12V is a sign of a significantly discharged battery.

- SOH & SOC: These are usually presented as percentages. Lower SOH percentages indicate a battery nearing the end of its life. Lower SOC means the battery is not fully charged.

- CCA (or Cranking Voltage): If your scanner provides CCA-related data, compare it to the manufacturer’s recommended CCA rating for your battery. A significantly lower CCA reading suggests reduced starting capability. Alternatively, observe the voltage drop during cranking (if your scanner offers this test). Excessive voltage drop during engine start can also indicate a weak battery or poor CCA performance.

-

Test Your Charging System (Optional but Recommended): Many OBD2 scanners can also assess your car’s charging system. After starting your engine, use the scanner to check the voltage again. A healthy charging system (alternator) should typically produce a voltage between 13.5V and 14.5V while the engine is running. This confirms the alternator is properly charging the battery.

By following these steps, you can effectively use an OBD2 scanner to read battery health and gain valuable insights into its condition.

Decoding OBD2 Codes Related to Battery and Electrical Systems

Beyond real-time readings, OBD2 scanners are invaluable for retrieving Diagnostic Trouble Codes (DTCs). These codes are generated by the car’s computer when it detects a problem in various systems, including the electrical system and battery. Understanding common OBD2 error codes related to battery and electrical issues is crucial for effective diagnosis.

Here are some common OBD2 error codes and their potential meanings:

-

P0562 – System Voltage Low: This code signals that the vehicle’s computer has detected a lower than expected system voltage. Potential causes include:

- Weak or Failing Battery: The battery may not be holding sufficient charge.

- Alternator Issues: The alternator might not be charging the battery effectively.

- Wiring Problems: Short circuits or breaks in the wiring can cause voltage drops.

- Excessive Electrical Load: Leaving lights or accessories on can drain the battery and trigger this code, especially if the charging system is marginal.

-

P2503 – Charging System Voltage Low: This code specifically points to a problem within the charging system. Likely culprits include:

- Failing Alternator: The alternator is not producing enough voltage to charge the battery.

- Loose or Corroded Alternator Connections: Poor connections can hinder proper charging.

- Faulty Voltage Regulator: The voltage regulator controls the alternator’s output; a malfunction can lead to undercharging.

-

P0563 – System Voltage High: This code indicates an abnormally high system voltage. Overvoltage can be just as damaging as undervoltage. Causes may include:

- Faulty Voltage Regulator: A malfunctioning regulator can cause the alternator to overcharge the battery.

- Alternator Overcharging: Internal alternator issues can lead to excessive voltage output.

- Wiring Issues: Although less common, wiring faults could theoretically contribute to overvoltage.

-

B1325 – Control Module Power Circuit Low: “B” codes typically refer to body electrical systems. B1325 suggests a voltage supply issue to a control module. This could be due to:

- Short Circuit: A short in the power circuit of a control module.

- Wiring Problem: Damaged or corroded wiring supplying power to the module.

- Faulty Control Module: In rare cases, the control module itself might be drawing excessive current or have an internal fault causing a voltage drop.

When you encounter these or other electrical-related OBD2 codes, it’s essential to investigate further. An OBD2 scanner is your starting point, providing the initial clue to potential problems within your car’s electrical system.

Beyond Battery Health: Detecting Electrical Shorts with OBD2

OBD2 scanners are not just for battery health; they can also aid in detecting electrical shorts, which are notoriously tricky to pinpoint. An electrical short occurs when an unintended path of low resistance allows current to bypass the intended circuit. This can lead to various problems, from blown fuses to component damage and even fires.

While an OBD2 scanner cannot tell you the exact location of a short, it can provide valuable clues by:

- Reading Error Codes: As discussed, codes like P0562 (System Voltage Low) or codes related to specific circuits (e.g., a code indicating a problem with a specific sensor or actuator circuit) can be a sign of a short. A short circuit can cause excessive current draw, leading to voltage drops and triggering these codes.

- Monitoring System Voltage: Unstable or fluctuating system voltage readings, especially when correlated with specific electrical events (like turning on lights or accessories), can suggest a short circuit drawing excessive current.

How to Use an OBD2 Scanner to Help Detect Shorts:

- Connect and Read Codes: Plug in your OBD2 scanner and retrieve any stored DTCs. Pay close attention to codes related to voltage issues or specific electrical circuits.

- Analyze the Codes: Codes like P0562 or circuit-specific fault codes warrant further investigation for potential shorts. Research the specific circuits implicated by the codes.

- Systematically Investigate: Based on the error codes, begin a visual inspection of the wiring and components related to the affected circuits. Look for:

- Frayed or Damaged Wires: Examine wiring harnesses, especially in areas prone to wear and tear or exposure to the elements.

- Loose Connections: Check connectors for looseness, corrosion, or damage.

- Signs of Overheating or Burning: Look for melted insulation or burn marks around wires, connectors, or components.

- Blown Fuses: Repeatedly blown fuses in a specific circuit are a strong indicator of a short.

Important Note: OBD2 scanners are diagnostic aids, not magic wands. Detecting shorts often requires a systematic approach, multimeter testing, wiring diagrams, and sometimes professional expertise. However, an OBD2 scanner can significantly narrow down the search area and guide your troubleshooting efforts.

Maintaining Your Car Battery and Electrical System for Longevity

Proactive maintenance is key to preventing battery and electrical system problems. Regular checks and preventative measures can significantly extend the life of your battery and electrical components, saving you from breakdowns and costly repairs.

Here are essential maintenance tips:

- Keep Battery Terminals Clean: Corrosion on battery terminals is a common issue that hinders proper charging and current flow. Regularly clean terminals with a mixture of baking soda and water, and use a terminal protector spray to prevent future corrosion.

- Regular Voltage Checks: Use an OBD2 scanner or a simple voltmeter to check your battery voltage periodically, especially if your car sits idle for extended periods or if you notice slow cranking. Aim for 12.6V at rest.

- Inspect Wiring Regularly: Periodically inspect your car’s wiring, particularly in the engine bay and undercarriage, for signs of fraying, cracking, or damage. Address any issues promptly by repairing or replacing damaged wiring.

- Monitor Alternator Performance: Use your OBD2 scanner to check the charging voltage while the engine is running (13.5V-14.5V). If the voltage is consistently outside this range, have your alternator tested professionally.

- Avoid Excessive Electrical Loads: Be mindful of leaving lights or accessories on for extended periods when the engine is off, as this can drain the battery unnecessarily.

- Battery Load Testing: Every few years, or if you suspect your battery is weakening, consider a professional battery load test. This test provides a more comprehensive assessment of the battery’s ability to deliver power under load.

Troubleshooting Steps After OBD2 Battery/Electrical Diagnosis

So, your OBD2 scanner has revealed a battery or electrical issue. What’s next?

If Your OBD2 Scanner Indicates a Potential Short Circuit:

- Visual Inspection: Conduct a thorough visual inspection of wiring, connectors, and components in the area indicated by the error code or your voltage readings.

- Fuse Check: Check fuses related to the affected circuit. Replace any blown fuses, but if a fuse blows repeatedly, it’s a strong sign of a short.

- Professional Diagnosis: If you cannot locate the short visually or are uncomfortable working with electrical systems, consult a qualified mechanic. Electrical shorts can be complex and require specialized tools and expertise to diagnose accurately.

If Your OBD2 Scanner Indicates Battery Issues:

- Battery Load Test: If your OBD2 readings suggest a weak battery, have a professional battery load test performed to confirm its condition.

- Consider Battery Age: Car batteries typically last 3-5 years. If your battery is in this age range and showing signs of weakness, replacement is likely the most practical solution.

- Check Alternator Output: Ensure your alternator is charging correctly. A faulty alternator can quickly drain or damage even a new battery. Use your OBD2 scanner or a voltmeter to verify charging voltage.

- Battery Replacement: If the battery is confirmed to be weak or failing, replace it with a new battery of the correct type and specification for your vehicle.

Conclusion

Understanding does OBD2 read battery health and how to utilize an OBD2 scanner for electrical system diagnostics is a powerful tool for any car owner. From checking battery voltage and state of health to detecting potential electrical shorts and deciphering error codes, an OBD2 scanner empowers you to proactively maintain your vehicle’s electrical well-being.

Whether you are a seasoned DIY enthusiast or simply want to be more informed about your car’s condition, investing in an OBD2 scanner and learning to use its electrical diagnostic features is a smart move. Regularly monitoring your battery and electrical system with an OBD2 scanner can help you avoid unexpected breakdowns, save money on repairs, and keep your car running reliably for years to come.

FAQs

How to check battery voltage with OBD2 scanner?

Connect your OBD2 scanner to your car’s diagnostic port, turn the ignition to “ON” (engine OFF), navigate to the “Battery” or “Voltage” section in the scanner menu, and read the displayed voltage. A healthy resting voltage is around 12.6V.

Will an OBD2 scanner read battery light?

Yes, an OBD2 scanner can help diagnose why your battery light is on. It can retrieve DTCs that indicate battery-related issues, such as low voltage, charging system problems, or other electrical faults triggering the light.

Can an OBD2 scanner test an alternator?

Yes, OBD2 scanners can assess alternator function by reading the charging voltage while the engine is running. A healthy alternator typically outputs between 13.5V and 14.5V. Readings outside this range may indicate alternator problems.