For car owners and enthusiasts alike, the world of automotive diagnostics can seem like a complex maze. However, modern vehicles are equipped with a powerful tool that simplifies troubleshooting: the On-Board Diagnostics II (OBD2) system. This system, mandated in most cars since 1996, acts as your car’s voice, communicating potential problems through a standardized set of Codes For Obd2, also known as Diagnostic Trouble Codes (DTCs). Understanding these codes is the first step towards effectively diagnosing and repairing your vehicle.

When your car’s computer, the Engine Control Unit (ECU), detects an issue, it stores a specific DTC in its memory. This is often accompanied by the dreaded “check engine light” illuminating on your dashboard. But don’t panic! These codes for OBD2 are not meant to be cryptic messages. They are structured in a way that provides valuable information about the nature and location of the problem, even before you consult a detailed chart. By using an OBD2 scanner, a relatively inexpensive and user-friendly tool, you can access these stored codes and begin to understand what your car is trying to tell you.

Breaking Down the Structure of OBD2 Codes

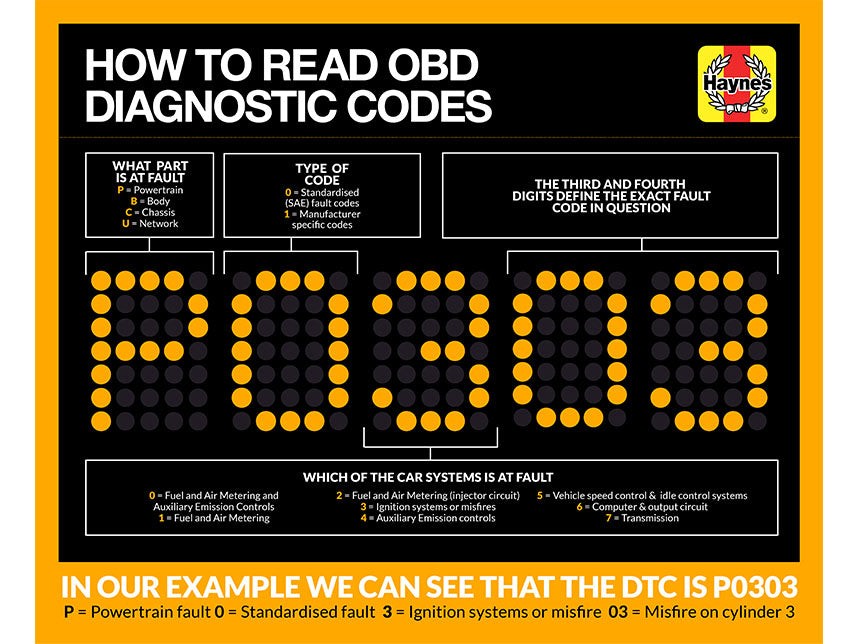

The beauty of the OBD2 system lies in its standardized code format. Each DTC is a five-character alphanumeric code that follows a specific pattern, allowing for a systematic approach to diagnosis. Let’s dissect the anatomy of these codes for OBD2 to empower you with the knowledge to interpret them effectively.

The five characters are broken down as follows:

-

The First Letter: Category of the Fault

The very first character of an OBD2 code is always a letter, and this letter immediately tells you the broad system within your vehicle that is experiencing the fault. There are four main categories:

- P (Powertrain): This is the most common category and refers to issues within the engine, transmission, and related components. Powertrain codes for OBD2 are often related to performance and emissions.

- B (Body): Body codes indicate problems with the car’s body systems, such as the airbags, power windows, central locking, and other comfort and convenience features.

- C (Chassis): Chassis codes relate to systems like braking, steering, and suspension. Issues in these areas can significantly impact vehicle safety and handling.

- U (Network): “U” codes indicate communication problems within the vehicle’s computer networks. Modern cars have complex communication systems, and these codes signal disruptions in data flow between different modules.

-

The First Number: Code Type

The first numerical digit following the letter further refines the code’s meaning and tells you whether the code is a standardized code or manufacturer-specific.

- 0 (Standardized SAE Code): A “0” indicates a standardized code defined by the Society of Automotive Engineers (SAE). These codes for OBD2 are generic across all makes and models, ensuring a common diagnostic language.

- 1 (Manufacturer-Specific Code): A “1” in this position signifies a manufacturer-specific code. While the general category is still defined by the letter, the specific meaning of these codes for OBD2 is defined by the car manufacturer and may require a more detailed lookup in a manufacturer-specific service manual.

-

The Second Number: Subsystem Affected

The second numerical digit provides even more granularity by pinpointing the specific subsystem within the broader category identified by the first letter. For Powertrain (P) codes, which are most frequently encountered, these digits represent:

- 0: Fuel and Air Metering and Auxiliary Emission Controls

- 1: Fuel and Air Metering

- 2: Fuel and Air Metering (injector circuit)

- 3: Ignition systems or misfires

- 4: Auxiliary emission controls

- 5: Vehicle speed control & idle control systems

- 6: Computer & output circuit

- 7: Transmission

-

The Third and Fourth Numbers: Specific Fault Identification

The final two digits, the third and fourth numbers, are the most specific. They pinpoint the exact nature of the fault within the identified subsystem. These numbers are sequential and are used to differentiate between various possible issues within each category and subsystem.

Example: Decoding P0303

Let’s take the example of the DTC P0303 and apply our newfound knowledge to decipher its meaning:

- P: Indicates a Powertrain fault – the issue is related to the engine or transmission.

- 0: Signifies a Standardized (SAE) code – this is a generic code applicable across different car brands.

- 3: Points to the Ignition system or misfires subsystem.

- 03: Specifically identifies a misfire on cylinder number 3.

Therefore, P0303 tells us there is a standardized Powertrain fault related to ignition or misfires, specifically on cylinder number 3. This detailed breakdown allows a mechanic or informed car owner to quickly narrow down the potential causes and begin targeted troubleshooting.

What are… Diagnostic Trouble Codes

What are… Diagnostic Trouble Codes

Understanding diagnostic trouble codes structure for car repair

Common OBD2 Trouble Codes Chart

While understanding the structure is crucial, having access to a list of common codes for OBD2 is incredibly helpful for quick reference. Below is a chart detailing some frequently encountered OBD2 codes and their descriptions. Keep in mind that this is not an exhaustive list, and specific vehicle models may have additional manufacturer-specific codes.

| Code | Code Identification |

|---|---|

| P0101 | Mass air flow (MAF) sensor circuit, range or performance problem |

| P0102 | Mass air flow (MAF) sensor circuit, low input |

| P0103 | Mass air flow (MAF) sensor circuit, high input |

| P0106 | Manifold absolute pressure (MAP) sensor circuit, range or performance problem |

| P0107 | Manifold absolute pressure (MAP) sensor circuit, low input |

| P0108 | Manifold absolute pressure (MAP) sensor circuit, high input |

| P0112 | Intake air temperature (IAT) circuit, low input |

| P0113 | Intake air temperature (IAT) circuit, high input |

| P0117 | Engine coolant temperature (ECT) circuit, low input |

| P0118 | Engine coolant temperature (ECT) circuit, high input |

| P0121 | Throttle position sensor (TPS) circuit, range or performance problem |

| P0122 | Throttle position sensor (TPS) circuit, low input |

| P0123 | Throttle position sensor (TPS) circuit, high input |

| P0125 | Insufficient coolant temperature for closed loop fuel control |

| P0131 | Oxygen sensor circuit, low voltage (pre-converter sensor, left bank) |

| P0132 | Oxygen sensor circuit, high voltage (pre-converter sensor, left bank) |

| P0133 | Oxygen sensor circuit, slow response (pre-converter sensor, left bank) |

| P0134 | Oxygen sensor circuit – no activity detected (pre-converter sensor, left bank) |

| P0135 | Oxygen sensor heater circuit malfunction (pre-converter sensor, left bank) |

| P0137 | Oxygen sensor circuit, low voltage (post-converter sensor, left bank) |

| P0138 | Oxygen sensor circuit, high voltage (post-converter sensor, left bank) |

| P0140 | Oxygen sensor circuit – no activity detected (post-converter sensor, left bank) |

| P0141 | Oxygen sensor heater circuit malfunction (post-converter sensor, left bank) |

| P0143 | Oxygen sensor circuit, low voltage (#2 post-converter sensor, left bank) |

| P0144 | Oxygen sensor circuit, high voltage (#2 post-converter sensor, left bank) |

| P0146 | Oxygen sensor circuit – no activity detected (#2 post-converter sensor, left bank) |

| P0147 | Oxygen sensor heater circuit malfunction (#2 post-converter sensor, left bank) |

| P0151 | Oxygen sensor circuit, low voltage (pre-converter sensor, right bank) |

| P0152 | Oxygen sensor circuit, high voltage (pre-converter sensor, right bank) |

| P0153 | Oxygen sensor circuit, slow response (pre-converter sensor, right bank) |

| P0154 | Oxygen sensor circuit – no activity detected (pre-converter sensor, right bank) |

| P0155 | Oxygen sensor heater circuit malfunction (pre-converter sensor, right bank) |

| P0157 | Oxygen sensor circuit, low voltage (post-converter sensor, right bank) |

| P0158 | Oxygen sensor circuit, high voltage (post-converter sensor, right bank) |

| P0160 | Oxygen sensor circuit – no activity detected (post-converter sensor, right bank) |

| P0161 | Oxygen sensor heater circuit malfunction (post-converter sensor, right bank) |

| P0171 | System too lean, left bank |

| P0172 | System too rich, left bank |

| P0174 | System too lean, right bank |

| P0175 | System too rich, right bank |

| P0300 | Engine misfire detected |

| P0301 | Cylinder number 1 misfire detected |

| P0302 | Cylinder number 2 misfire detected |

| P0303 | Cylinder number 3 misfire detected |

| P0304 | Cylinder number 4 misfire detected |

| P0305 | Cylinder number 5 misfire detected |

| P0306 | Cylinder number 6 misfire detected |

| P0307 | Cylinder number 7 misfire detected |

| P0308 | Cylinder number 8 misfire detected |

| P0325 | Knock sensor circuit malfunction |

| P0327 | Knock sensor circuit, low output |

| P0336 | Crankshaft position sensor circuit, range or performance problem |

| P0337 | Crankshaft position sensor, low output |

| P0338 | Crankshaft position sensor, high output |

| P0339 | Crankshaft position sensor, circuit intermittent |

| P0340 | Camshaft position sensor circuit |

| P0341 | Camshaft position sensor circuit, range or performance problem |

| P0401 | Exhaust gas recirculation, insufficient flow detected |

| P0404 | Exhaust gas recirculation circuit, range or performance problem |

| P0405 | Exhaust gas recirculation sensor circuit low |

| P0410 | Secondary air injection system |

| P0418 | Secondary air injection pump relay control circuit |

| P0420 | Catalyst system efficiency below threshold, left bank |

| P0430 | Catalyst system efficiency below threshold, right bank |

| P0440 | Evaporative emission control system malfunction |

| P0441 | Evaporative emission control system, purge control circuit malfunction |

| P0442 | Evaporative emission control system, small leak detected |

| P0446 | Evaporative emission control system, vent system performance |

| P0452 | Evaporative emission control system, pressure sensor low input |

| P0453 | Evaporative emission control system, pressure sensor high input |

| P0461 | Fuel level sensor circuit, range or performance problem |

| P0462 | Fuel level sensor circuit, low input |

| P0463 | Fuel level sensor circuit, high input |

| P0500 | Vehicle speed sensor circuit |

| P0506 | Idle control system, rpm lower than expected |

| P0507 | Idle control system, rpm higher than expected |

| P0601 | Powertrain Control Module, memory error |

| P0602 | Powertrain Control module, programming error |

| P0603 | Powertrain Control Module, memory reset error |

| P0604 | Powertrain Control Module, memory error (RAM) |

| P0605 | Powertrain Control Module, memory error (ROM) |

* Note: Not all codes are applicable to all vehicle models. Always consult your vehicle’s service manual for specific information.

Utilizing an OBD2 Scanner

Reading codes for OBD2 is straightforward with an OBD2 scanner. These scanners plug into the OBD2 port, typically located under the dashboard on the driver’s side. Once connected, the scanner can communicate with your car’s ECU and display any stored DTCs. Many scanners also offer additional features like clearing codes (after repairs are made) and providing live engine data.

In Conclusion

Understanding codes for OBD2 empowers you to take a more proactive role in your car’s maintenance. While DTCs provide a valuable starting point for diagnosis, they are not always a definitive answer. Further investigation and troubleshooting are often required to pinpoint the root cause of the problem. However, by learning to decipher these codes, you can communicate more effectively with mechanics, perform your own basic repairs, and ultimately keep your vehicle running smoothly and efficiently.