If you drive a General Motors vehicle and have encountered the OBD2 code P1870, you’re likely experiencing a transmission issue related to component slippage. This code, specific to GM vehicles, signals that your Powertrain Control Module (PCM) has detected an unexpected difference between engine speed and vehicle speed after the torque converter clutch is engaged. As a seasoned mechanic at techcarusa.com, I’m here to break down what this code means, its potential causes, and how to approach diagnosing and fixing it.

Decoding P1870: Transmission Slippage Explained

The P1870 code is triggered when the PCM, the brain of your vehicle’s engine and transmission management system, notices that the relationship between engine RPM and vehicle speed is off while cruising in high gear or overdrive, specifically when the torque converter clutch (TCC) is supposed to be locked.

Think of it this way: when your torque converter clutch engages, it creates a more direct connection between the engine and transmission, aiming for a specific RPM-to-speed ratio. If the PCM detects that the actual ratio deviates significantly from the expected parameters, it interprets this as “slippage” within the transmission. This discrepancy sets the P1870 code and often prompts the PCM to take immediate protective actions.

When P1870 is set, the PCM typically responds by:

- Increasing Transmission Line Pressure: The PCM commands higher main line pressure in the transmission. This is a safety measure intended to increase clamping force on the clutches and bands, hoping to stop further slippage and prevent damage.

- Disabling Torque Converter Clutch Apply: To prevent further potential damage from slippage, the PCM will disengage the torque converter clutch.

- Potentially Inhibiting 4th Gear: In some cases, the PCM might prevent the transmission from shifting into 4th gear (overdrive) as an additional safety precaution.

- Possible MIL Illumination: The Malfunction Indicator Lamp (MIL), or check engine light, may or may not illuminate depending on the specific vehicle and the severity of the detected slippage.

This code is often associated with a complaint of a hard 1-2 upshift. This is a side effect of the PCM increasing line pressure to compensate for the perceived slippage. The increased pressure can make gear changes feel firmer, sometimes even harsh.

Common Causes of Chevy OBD2 Code P1870

Pinpointing the exact cause of P1870 can involve some detective work, as various issues can lead to transmission slippage. Here are some of the most frequent culprits:

- Low Transmission Fluid Level: Insufficient transmission fluid is a common and often overlooked cause. Low fluid can lead to inadequate lubrication and hydraulic pressure, directly impacting clutch and band performance and causing slippage.

- Torque Converter Clutch Failure: The torque converter clutch itself is a prime suspect. Problems within the TCC mechanism, such as worn linings or mechanical failures, can prevent proper engagement and cause slippage.

- Valve Body Issues: The valve body is the hydraulic control center of your transmission. Wear and tear within the valve body, particularly in valves related to TCC control, can lead to pressure leaks and improper TCC operation, resulting in P1870. Specific valves often implicated include:

- Isolator Valve and TCC Regulator Valve: Wear in the bores of these valves is a well-documented issue, leading to reduced TCC apply pressure.

- Actuator Feed Limit Valve: This valve supplies pressure to the PWM solenoid. If it malfunctions or its bore is worn, it can restrict pressure to the PWM solenoid, hindering proper TCC control.

- TCC ON/OFF Solenoid and Converter Clutch Valve: Malfunctions in these components can directly impact the TCC’s ability to engage and disengage correctly.

- Internal Transmission Component Wear: While less common than valve body or TCC issues in relation to P1870, wear in other internal transmission components like clutches and bands themselves can also cause slippage.

- Hydraulic Circuit Problems: Leaks or blockages in the hydraulic circuits that control the TCC can disrupt fluid flow and pressure, leading to slippage.

- Electronic Control Issues: Problems with the wiring or the PCM itself, though less frequent, could theoretically cause miscommunication or incorrect signals to the TCC solenoid, resulting in improper TCC operation and P1870.

Let’s delve deeper into how these issues manifest in specific GM transmissions like the 4L60-E and 4L80-E, which are known to be susceptible to P1870.

P1870 in GM 4L60-E and 4L80-E Transmissions

The GM 4L60-E and 4L80-E transmissions are known for their robustness, but like any mechanical system, they are not immune to wear and tear. Code P1870 is a relatively common complaint in these transmissions, often pointing to specific failure patterns.

4L60-E Transmission and P1870

In the 4L60-E, when operating in overdrive, several components are engaged: the forward clutch, the 3-4 clutches, and the 2-4 band, in addition to the torque converter clutch. When P1870 occurs in a 4L60-E, the fault could potentially lie in any of these components, their hydraulic controls, or the electronic controls.

However, experience has shown that in the 4L60-E, torque converter clutch failure, often due to valve body wear, is the most frequent cause of P1870. Specifically, wear in the bores of the isolator valve and TCC regulator valve within the valve body is a well-known issue. This wear leads to internal leaks, reducing the pressure available to apply the torque converter clutch effectively, causing slippage, and triggering the P1870 code.

4L80-E Transmission and P1870

For the heavier-duty 4L80-E transmission, while valve body wear can also be a factor, a cracked torque converter clutch piston is often cited as a common cause of P1870. A crack in the piston can lead to pressure loss, preventing proper clutch engagement and resulting in slippage.

Evolution of Torque Converter Clutch Technology in GM Transmissions

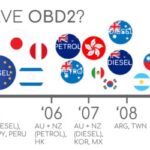

Understanding the evolution of torque converter clutch technology in GM transmissions provides valuable context for diagnosing P1870, especially in older vehicles. GM has implemented several strategies over the years to improve fuel economy and driveability through torque converter clutch control.

Early ON/OFF TCC Systems (Pre-1995 4L60-E)

In early 4L60-E transmissions (1993-1994), a simple ON/OFF solenoid controlled the TCC. These systems used a basic encapsulated check ball assembly to manage clutch apply.

Introduction of PWM (Pulse Width Modulation) TCC (1995+ 4L60-E)

Starting in 1995, GM introduced Pulse Width Modulation (PWM) to the torque converter clutch control in the 4L60-E. This significant change involved adding a PWM solenoid, which allowed for gradual and controlled application of the TCC. This PWM system offered smoother engagement and improved fuel economy by allowing for some controlled slip during TCC apply. This required modifications to the pump assembly and valve body to accommodate the new hydraulic requirements.

Image: A typical PWM (Pulse Width Modulation) solenoid used in later 4L60-E transmissions for controlling torque converter clutch application.

The PWM solenoid works by regulating pressure in the TCC hydraulic circuit based on a duty cycle commanded by the PCM. A higher duty cycle increases pressure, leading to firmer clutch engagement, while a lower duty cycle reduces pressure and allows for more slip.

Electronically Controlled Clutch Capacity (ECCC/EC3) (1997+ GM)

Further advancements led to Electronically Controlled Clutch Capacity (ECCC), also known as EC3. Starting in 1997 and becoming more widespread in 1998 and later models, ECCC strategies allowed for continuous, controlled slip of the torque converter clutch, even in lower gears like 2nd gear, and at cruising speeds below full lock-up. This strategy aimed to further optimize fuel economy and refine shift feel.

ECCC systems required significant changes:

- Clutch Lining Material: ECCC systems transitioned to carbon-based woven clutch linings to withstand the continuous slip, replacing earlier cellulose-based (paper) or Kevlar-based linings.

- Damper Plate Springs: The damper plate springs within the torque converter, which act as shock absorbers, were made progressively softer to accommodate the smoother, slipping clutch engagement of PWM and ECCC strategies.

Image: A visual comparison of different torque converter clutch lining materials, including carbon-based woven linings used in ECCC systems.

These advancements, while improving efficiency and driveability, also introduced new potential points of failure and complexities in diagnosis, particularly when dealing with P1870 in vehicles with PWM or ECCC systems.

Diagnosing Chevy P1870: A Step-by-Step Approach

Diagnosing P1870 requires a systematic approach. Here’s a step-by-step guide:

-

Initial Scan and Verification:

- Use an OBD2 scanner to confirm the presence of the P1870 code and check for any other related codes.

- Record all codes and freeze frame data, which can provide valuable clues about the conditions when the code was set.

- Clear the codes and test drive the vehicle to see if the P1870 code returns. This verifies if the issue is consistent or intermittent.

-

Check Transmission Fluid:

- Inspect the transmission fluid level and condition.

- Low fluid level is a common cause and easy to rectify.

- Check for burnt smell or unusual color, which can indicate internal transmission damage or overheating.

-

Monitor Transmission Data with a Scanner:

- Use a scan tool to monitor live data PIDs (Parameter IDs) related to the torque converter clutch. Key PIDs to observe include:

- TCC Enabled (Yes/No): Indicates whether the PCM is commanding the TCC to be on or off.

- PWM Solenoid Duty Cycle Percentage: For PWM systems, this shows the duty cycle being commanded by the PCM to the PWM solenoid, controlling TCC apply pressure.

- Converter Slip RPM: This crucial PID displays the actual slippage occurring in the torque converter. Excessive slip RPM when the TCC is commanded ON is a strong indicator of a problem.

Image: A scan tool display showing relevant PIDs (Parameter IDs) for diagnosing torque converter clutch operation, including TCC Enabled, PWM Duty Cycle, and Converter Slip RPM.

- Observe TCC operation during test drive: Monitor these PIDs while driving under conditions where the TCC should engage (cruising speed in high gear/overdrive). Look for:

- Does the TCC Enable command switch to “Yes”?

- Is the PWM duty cycle changing (if applicable)?

- Is the Converter Slip RPM within acceptable limits (ideally close to zero when locked, or a controlled slip in ECCC systems)?

- Does the P1870 code set during the test drive, and under what conditions?

- Use a scan tool to monitor live data PIDs (Parameter IDs) related to the torque converter clutch. Key PIDs to observe include:

-

Valve Body Inspection (If Suspected):

- If scanner data points to a TCC control issue and fluid level/condition are good, valve body problems become a prime suspect, especially in 4L60-E transmissions.

- Valve body inspection is a more involved step, potentially requiring removal and disassembly of the valve body to check for valve bore wear, sticking valves, and other damage. This often requires specialized knowledge and tools.

-

Torque Converter Inspection (If Suspected):

- If valve body issues are ruled out or after valve body repair/replacement, and P1870 persists, the torque converter itself should be investigated.

- Torque converter diagnosis can involve pressure testing or, in some cases, removal and inspection of the torque converter for internal damage, clutch wear, or piston cracks (especially in 4L80-E).

-

Check Wiring and Solenoids:

- Inspect wiring harnesses and connectors related to the TCC solenoid and PWM solenoid for damage, corrosion, or loose connections.

- Test the resistance and operation of the TCC solenoid and PWM solenoid using a multimeter to ensure they are functioning electrically.

Repairing P1870: Solutions and Considerations

The repair strategy for P1870 depends heavily on the root cause identified during diagnosis.

- Low Fluid: If low fluid is the issue, simply topping off the transmission fluid to the correct level might resolve the problem. However, investigate for leaks if the fluid was significantly low.

- Valve Body Wear: Valve body wear, particularly in 4L60-E transmissions, is a common repair scenario. Solutions include:

- Valve Body Reaming and Oversized Valves: Aftermarket companies offer reamer kits and oversized valves to repair worn valve bores, restoring proper hydraulic sealing. Kits are available for valves like the isolator valve, TCC regulator valve, and actuator feed limit valve.

- Valve Body Replacement: In cases of severe wear or damage, replacing the entire valve body assembly might be necessary.

- Torque Converter Replacement: If the torque converter itself is faulty (e.g., cracked piston, worn clutch), replacement is the typical solution. When replacing the torque converter, ensure you use the correct type and specification for your vehicle and transmission (especially considering ON/OFF, PWM, or ECCC system compatibility).

- Solenoid Replacement: If a TCC solenoid or PWM solenoid is found to be faulty, replacing the solenoid is a straightforward repair.

- Transmission Rebuild: In cases of extensive internal transmission wear or damage, a complete transmission rebuild might be the most comprehensive and long-term solution.

Preventive Measures and Maintenance:

- Regular Transmission Fluid Changes: Following the manufacturer’s recommended transmission fluid change intervals is crucial for maintaining transmission health and preventing wear.

- Consider an Inline Transmission Filter: Adding an aftermarket inline transmission filter to the cooler lines can provide finer filtration (down to 20-25 microns) than the stock internal filter, helping to remove abrasive particles and extend transmission component life.

Conclusion: Addressing Chevy OBD2 Code P1870

Chevy Obd2 Code P1870 indicates transmission component slippage, most often related to issues within the torque converter clutch system, particularly in GM 4L60-E and 4L80-E transmissions. While valve body wear and torque converter clutch failure are frequent causes, a thorough diagnostic process is essential to pinpoint the exact problem.

By understanding the function of the torque converter clutch, the evolution of TCC control systems in GM vehicles, and following a systematic diagnostic approach, you can effectively address P1870 and ensure the long-term health and performance of your vehicle’s transmission. Remember to consult a qualified automotive technician if you are not comfortable performing these diagnostic and repair procedures yourself.