Experiencing issues when your OBD2 scanner fails to communicate with your vehicle’s Engine Control Unit (ECU) can be incredibly frustrating. While there are numerous potential reasons behind this communication breakdown, one often-overlooked culprit is a defective ignition switch.

This article delves into the crucial role of the ignition switch in OBD2 communication, explores how a faulty switch can lead to communication errors, and provides practical diagnostic steps to resolve these issues. We’ll cover not just the ignition switch, but also other common causes of OBD2 communication problems, ensuring you have a comprehensive understanding to troubleshoot effectively.

The Vital Role of the Ignition Switch in OBD2 Communication

The ignition switch in your car is more than just a key slot or start button; it’s a central command center for your vehicle’s electrical systems. It acts as the gateway for power distribution, directing electricity to various components essential for your car to run and for diagnostic tools like OBD2 scanners to function. Crucially, this includes the ECU, the brain of your vehicle, which must be powered to communicate with an OBD2 scanner.

When you turn your ignition key to the “ON” or “RUN” position (or press the start button in modern vehicles), you’re initiating a sequence of electrical events. The ignition switch is responsible for sending power to the ECU, sensors, and the OBD2 port itself. This power supply is not just necessary – it’s fundamental for establishing communication between the OBD2 scanner and the ECU. Without a stable and sufficient power supply from the ignition switch, the ECU may remain offline or operate erratically, preventing the OBD2 scanner from accessing vital diagnostic information.

Think of the ignition switch as a power router in your home. Just as your router needs to be powered on to allow your devices to connect to the internet, the ignition switch must be functioning correctly to power the ECU and enable OBD2 communication. If the switch is faulty, it can interrupt this power flow, leading to a communication dead end.

How a Faulty Ignition Switch Disrupts OBD2 Communication

A malfunctioning ignition switch can manifest in several ways, all of which can negatively impact the ability of your OBD2 scanner to communicate with your vehicle’s computer system. Let’s examine the primary ways a defective switch can cause these communication errors:

No Power Delivery to the ECU

The most direct way a faulty ignition switch can disrupt OBD2 communication is by failing to deliver power to the ECU. If the switch is internally damaged or worn, it may not complete the electrical circuit required to power up the ECU when turned to the “ON” position.

In this scenario, the ECU is effectively “off” even when the ignition is seemingly engaged. Consequently, when you plug in your OBD2 scanner, it will find no responsive ECU to communicate with. The scanner might display a “communication error,” “link error,” or simply fail to establish a connection. Without power, the ECU cannot perform its essential functions, let alone transmit diagnostic data to the OBD2 scanner. It’s like trying to call someone on a phone that’s completely out of battery – no communication is possible.

Intermittent Power Supply Issues

Sometimes, an ignition switch might not fail completely but instead become intermittent in its operation. This means it might sporadically provide power and then cut it off, leading to inconsistent and unreliable communication.

When the ignition switch delivers power intermittently, the ECU might power up and become accessible to the OBD2 scanner for brief periods, only to lose power and disconnect unexpectedly. This can result in frustrating situations where your OBD2 scanner might connect sometimes, but the connection is unstable and drops frequently. You might experience incomplete data readings, interruptions during diagnostic scans, or failure to retrieve diagnostic trouble codes (DTCs). Diagnosing the root cause becomes significantly more challenging with such intermittent issues, as the problem might seem to come and go.

Partial Electrical Failures within the Switch

In more complex cases, an ignition switch might suffer from partial electrical failures. This means that while some circuits within the switch might function correctly, others might be compromised. It’s possible for the ignition switch to power some vehicle systems, such as the dashboard lights or radio, while failing to properly power the ECU and OBD2 system.

In such a scenario, you might observe that your car seems partially functional – perhaps the dashboard lights up when you turn the key – but the OBD2 scanner still fails to connect. This is because the specific circuit within the ignition switch responsible for powering the ECU and OBD2 port is malfunctioning, even though other circuits are operating normally. This type of partial failure can be particularly misleading as it might initially suggest that the ignition switch is not the problem, since some electrical functions are still working.

Beyond the Ignition Switch: Common Reasons for OBD2 Communication Failure

While a defective ignition switch is a potential cause of OBD2 communication problems, it’s important to consider other, more common culprits before assuming the switch is at fault. Systematic diagnosis is key to pinpointing the actual issue. Here are several other frequent reasons why your OBD2 scanner might not be communicating:

Blown Fuse

A blown fuse is one of the simplest and most common reasons for OBD2 communication issues. The OBD2 port and the ECU are typically protected by fuses in your vehicle’s electrical system. If there’s a power surge or short circuit, these fuses can blow to protect the sensitive electronic components.

To check for blown fuses, locate your vehicle’s fuse box (usually under the dashboard or in the engine compartment; consult your owner’s manual for the exact location). Inspect the fuses related to the OBD2 port and the ECU (again, your owner’s manual will provide fuse diagrams and descriptions). A blown fuse will often have a broken filament visible through its clear plastic housing. Replacing a blown fuse is a straightforward fix, but it’s crucial to identify and resolve the underlying cause of the fuse blowing to prevent recurrence.

Faulty OBD2 Port

The OBD2 port itself can be a source of communication problems. Being located in an accessible area, often under the dashboard, it’s susceptible to physical damage, loose connections, and the accumulation of dirt and debris.

Check the OBD2 port for any signs of physical damage, such as bent or broken pins. Ensure that the port is securely mounted and not loose. Inspect for dirt, corrosion, or obstructions within the port. Sometimes, simply cleaning the OBD2 port with compressed air or a contact cleaner can resolve connection issues. A loose or damaged port can prevent the OBD2 scanner from making proper electrical contact, leading to communication failure.

Wiring Issues

The wiring harness connecting the OBD2 port to the ECU and the vehicle’s power supply can degrade over time due to wear and tear, heat exposure, moisture, or corrosion. Damaged wiring can interrupt the communication signals and power supply required for the OBD2 system to function.

Inspect the wiring harness leading to the OBD2 port for any visible signs of damage, such as frayed wires, cracked insulation, or corroded connectors. Pay close attention to areas where the wiring might be exposed to movement or harsh conditions. Wiring problems can be more challenging to diagnose and repair, often requiring specialized tools and knowledge of automotive electrical systems.

Low Battery Voltage

An OBD2 scanner relies on a certain voltage level from the vehicle’s battery to operate correctly. If your car battery is weak, discharged, or failing, it might not provide sufficient voltage to power the OBD2 system adequately, leading to communication problems.

Ensure your vehicle’s battery is properly charged and in good condition. A healthy car battery typically reads around 12.6 volts when the engine is off. If the voltage is significantly lower, consider charging or replacing the battery. Low battery voltage can not only affect OBD2 communication but also cause a wide range of other electrical and starting issues in your vehicle.

Faulty ECU

While less common than other causes, a malfunctioning ECU itself can prevent OBD2 communication. The ECU is a complex electronic control unit, and like any electronic device, it can fail. However, ECU failure is usually accompanied by other noticeable vehicle performance issues beyond just OBD2 communication problems.

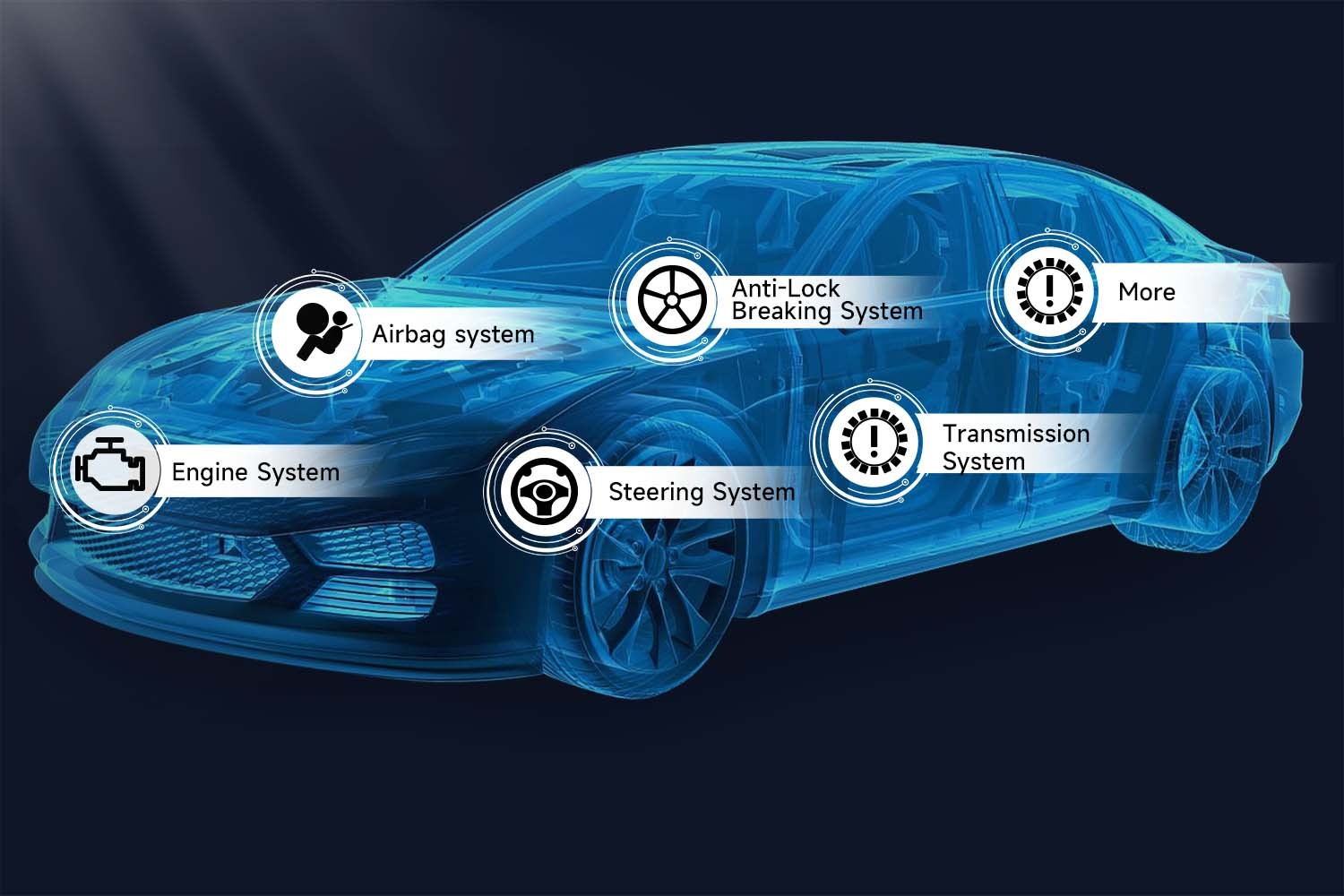

If you suspect a faulty ECU, you might experience various symptoms such as engine performance problems, transmission issues, or warning lights on the dashboard. Diagnosing an ECU failure often requires professional diagnostic equipment and expertise. It’s usually considered a diagnosis of exclusion, meaning other more common causes should be ruled out first.

Practical Steps for Troubleshooting OBD2 Communication Problems

When faced with OBD2 communication issues, a systematic approach is essential for efficient diagnosis and repair. Here are practical steps you can take to troubleshoot the problem:

-

Verify Basic Connections and Ignition Status:

- Ensure the ignition switch is in the “ON” or “RUN” position. This is the most fundamental step, often overlooked.

- Double-check that your OBD2 scanner is securely plugged into the OBD2 port. A loose connection is a common cause of communication failure.

- If your scanner has a wired connection, inspect the cable for damage. If it’s wireless (Bluetooth), ensure it’s properly paired and connected according to the manufacturer’s instructions.

-

Check Vehicle Fuses:

- Locate your vehicle’s fuse box diagram (usually in your owner’s manual or on the fuse box cover).

- Identify the fuses related to the OBD2 port and ECU.

- Visually inspect these fuses for blown filaments. Replace any blown fuses with new fuses of the same amperage rating.

-

Inspect the OBD2 Port:

- Visually examine the OBD2 port for any physical damage, bent pins, or looseness.

- Clean the port with compressed air or a plastic-safe contact cleaner to remove any dirt or debris that might be obstructing the connection.

-

Assess Battery Voltage:

- Use a multimeter to check your vehicle’s battery voltage. A healthy battery should read approximately 12.6 volts with the engine off.

- If the voltage is low, try charging the battery or jump-starting the car if necessary. See if OBD2 communication is restored with a healthy battery voltage.

-

Consider Professional Diagnosis:

- If you’ve checked the fuses, OBD2 port, battery, and ignition switch (as best you can without specialized equipment) and are still experiencing communication issues, it might be time to seek professional help.

- A qualified mechanic or automotive technician has advanced diagnostic tools and expertise to pinpoint more complex electrical problems, including deeper ignition switch issues, wiring faults, or ECU malfunctions.

Conclusion

While a defective ignition switch might not be the first thing that comes to mind when troubleshooting OBD2 communication errors, it’s a potential cause that should not be dismissed. By understanding the ignition switch’s role in powering the ECU and OBD2 system, and by systematically checking other common causes like fuses, the OBD2 port itself, and battery voltage, you can effectively diagnose and resolve many OBD2 communication problems. Remember to approach troubleshooting methodically, starting with the simplest and most common causes first, and don’t hesitate to seek professional assistance when needed.

FAQs

What would cause the OBD2 port to stop working?

Several factors can cause an OBD2 port to stop working. Common causes include a blown fuse in the OBD2 circuit, damaged or corroded wiring leading to the port, physical damage to the port itself (bent pins, loose connector), or low vehicle battery voltage.

Why is my OBD2 scanner not connecting to the ECU?

An OBD2 scanner might fail to connect to the ECU due to a variety of reasons. These include a faulty ignition switch preventing power delivery to the ECU, a blown fuse in the ECU or OBD2 circuit, wiring problems between the OBD2 port and the ECU, a weak or discharged car battery, or, in rare cases, a malfunction within the ECU itself.

Why is my OBD scanner not picking up any diagnostic codes?

If your OBD scanner is not picking up any diagnostic codes, it could be due to several reasons. There might be no current fault codes stored in the ECU. Alternatively, the scanner might not be communicating properly with the ECU due to issues like no power to the ECU (possibly from a faulty ignition switch), connection problems with the scanner or OBD2 port, or the codes might have been recently cleared and have not yet reappeared.