Navigating the world of OBD2 diagnostics often involves interpreting various parameters to understand engine performance. While Calculated Load Value is a commonly known metric, Absolute Load Value Obd2 offers a deeper insight into what’s happening under the hood. But what exactly is Absolute Load Value, and how can it enhance your diagnostic capabilities?

To truly grasp absolute load value obd2, it’s helpful to contrast it with its more familiar counterpart, Calculated Load. Calculated Load Value, as defined by SAE, is designed to reach 1.0 (or 100%) at Wide Open Throttle (WOT) for any engine, regardless of altitude, temperature, or engine RPM. It’s essentially a percentage of peak available torque and is often used for power enrichment scheduling.

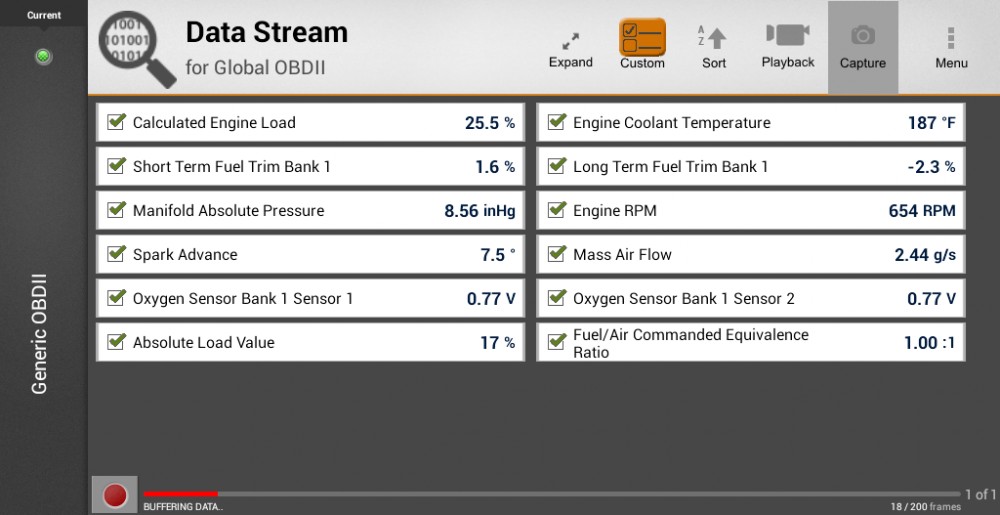

OBD2 data capture showing Absolute Load Value and Calculated Load Value at idle on a Mazda 3 after throttle body swap, demonstrating engine load parameters for diagnostic analysis.

OBD2 data capture showing Absolute Load Value and Calculated Load Value at idle on a Mazda 3 after throttle body swap, demonstrating engine load parameters for diagnostic analysis.

However, absolute load value obd2 presents a different perspective. According to SAE documentation, Absolute Load Value ranges from 0 to approximately 0.95 for naturally aspirated engines and can go up to 4.0 for boosted engines. Crucially, it’s linearly correlated with both engine indicated and brake torque, making it a direct indicator of engine output. Furthermore, the peak value of absolute load value obd2 aligns with volumetric efficiency at WOT, giving technicians a valuable metric for assessing engine breathing and pumping efficiency for diagnostic purposes.

The key takeaway here is the diagnostic potential. While Calculated Load is useful, absolute load value obd2 directly reflects engine pumping efficiency and volumetric efficiency. This makes it particularly insightful when diagnosing engine breathing issues, such as intake restrictions or exhaust blockages. Imagine evaluating an engine’s performance under load – absolute load value obd2 can reveal subtle inefficiencies that Calculated Load might overlook.

So, should you prioritize absolute load value obd2 over Calculated Load? Not necessarily. Both PIDs offer unique perspectives. However, incorporating absolute load value obd2 into your diagnostic routine can provide a more comprehensive understanding of engine performance, especially when investigating volumetric efficiency and potential pumping losses. By monitoring both Calculated and Absolute Load Values, technicians gain a richer dataset for pinpointing engine issues and ensuring optimal vehicle performance.