As a car owner or fleet manager, encountering a check engine light can be unsettling. Modern vehicles, especially those compliant with OBD2 standards, possess a sophisticated communication system to alert you about potential issues. You might have heard about OBD2 codes, but are they universal? Understanding the nature of these codes is crucial for effective vehicle maintenance and diagnostics.

In this guide, we will delve into the world of OBD2 codes, clarifying whether they are indeed universal and how to interpret them to keep your vehicles running smoothly. We’ll explore the standardized aspects and manufacturer-specific nuances of OBD2 codes, providing you with a comprehensive understanding for better vehicle care.

What Exactly Are OBD2 Codes?

On-Board Diagnostics II (OBD2) codes are essentially standardized messages generated by your vehicle’s computer system. Think of them as your car’s way of telling you something isn’t quite right under the hood or within its various systems.

Modern vehicles are equipped with an intricate network of sensors and control units monitoring various components, from the engine and transmission to emissions and safety systems. When the onboard computer detects a problem or a reading outside of the expected parameters, it generates an OBD2 code.

These codes are designed to indicate a wide spectrum of issues, ranging from minor glitches to more serious malfunctions. The illumination of the “Check Engine” light on your dashboard is often the first sign that an OBD2 code has been triggered, signaling that a system or component isn’t performing as it should.

To access these codes, you can use an OBD2 scanner. This device plugs into the OBD2 port, which is typically located beneath the dashboard on the driver’s side. Once connected, the scanner retrieves the stored trouble codes, providing a numerical or alphanumeric code that points towards the source of the problem.

This code serves as a starting point for diagnosis, guiding you or a qualified mechanic in identifying the specific area or component that requires attention. It’s a valuable tool for troubleshooting and making informed decisions about vehicle maintenance and repair.

Are OBD2 Codes Really Universal? Unpacking Standardization and Specificity

The question of whether OBD2 codes are universal is not a simple yes or no. The answer lies in understanding the different layers of the OBD2 standard. While there’s a significant degree of standardization, manufacturer-specific codes also play a crucial role.

The Universal Aspect: Standardized Codes

A core element of the OBD2 standard is the set of standardized or generic codes. These codes are indeed universal, meaning they are consistent across all vehicle makes and models that comply with OBD2 regulations (which is mandatory for most vehicles sold in the US since 1996 and in many other countries).

These standardized codes are defined by the SAE (Society of Automotive Engineers) and are typically used for common powertrain and emission-related issues. They are designed to cover problems that are generally consistent across different vehicle manufacturers. For example, a P0300 code will universally indicate a “Random/Multiple Cylinder Misfire Detected” regardless of whether you drive a Ford, Toyota, or BMW.

The Manufacturer-Specific Side: Enhanced Codes

While a significant portion of OBD2 codes are standardized, vehicle manufacturers also have the flexibility to add manufacturer-specific or enhanced codes. These codes go beyond the generic codes to provide more detailed diagnostics tailored to the specific systems and designs of a particular brand or model.

Manufacturer-specific codes often cover systems outside of the powertrain and emissions, such as body electronics, chassis systems, or advanced features unique to a specific manufacturer. For instance, a manufacturer might have a specific code for a fault in their proprietary navigation system or an advanced driver-assistance system (ADAS).

The Breakdown in Code Structure:

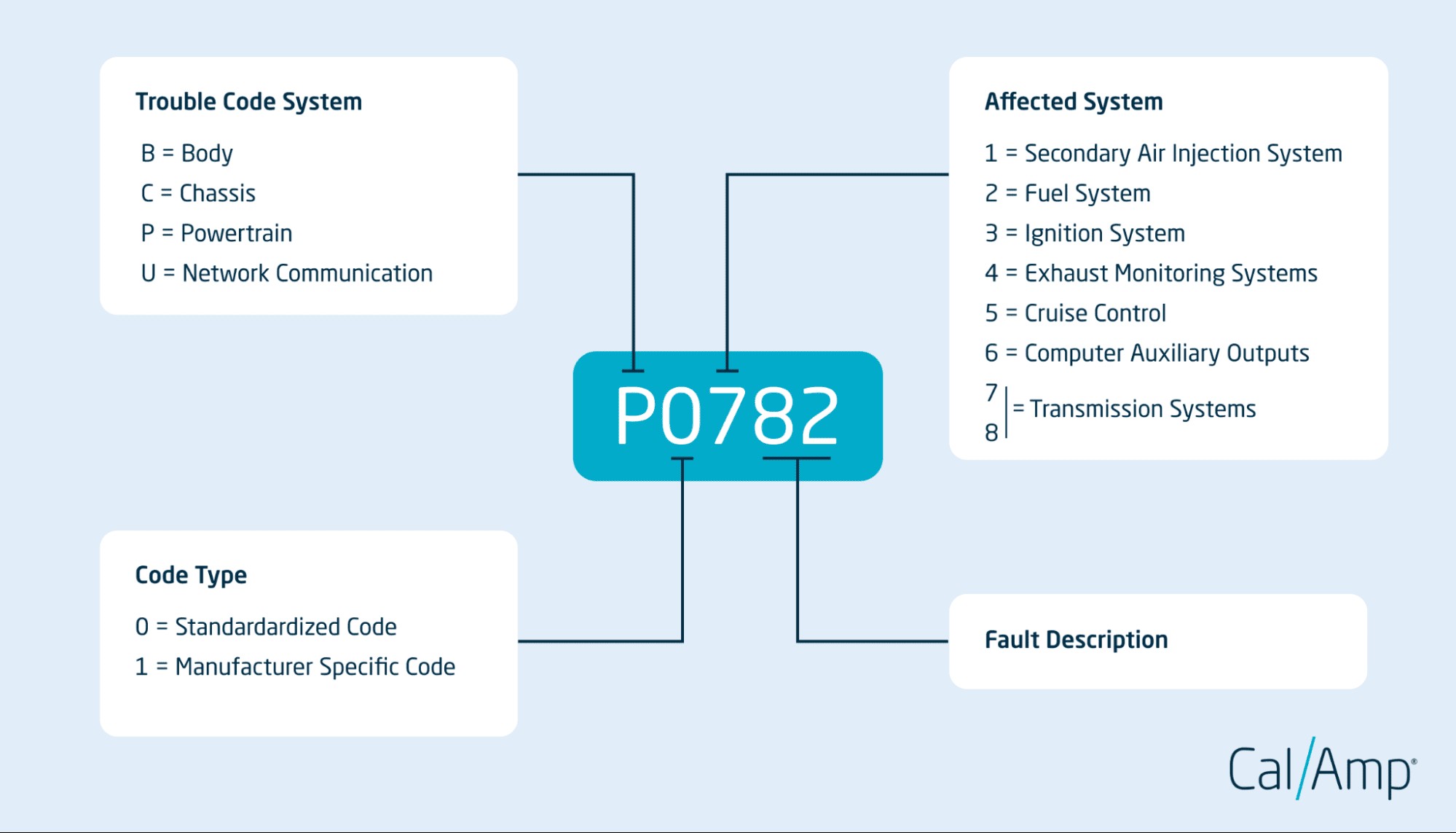

The structure of an OBD2 code itself reflects this duality of universal and specific elements:

- First Character (Letter): Indicates the primary system affected.

- P (Powertrain): Engine, transmission, and related systems.

- B (Body): Body electronics, interior systems, comfort features.

- C (Chassis): Mechanical systems, braking, suspension, steering.

- U (Network/Communication): Communication networks within the vehicle.

- Second Character (Digit): Indicates if the code is standardized or manufacturer-specific.

- 0: Standardized (Generic) OBD2 code.

- 1: Manufacturer-specific (Enhanced) OBD2 code.

- Third Character (Digit): Specifies the sub-system affected. (e.g., Fuel System, Ignition System, etc.)

- Fourth and Fifth Characters (Digits): Specific fault code number, further pinpointing the issue.

What OBD2 codes mean

What OBD2 codes mean

Understanding the Implications of Universality and Specificity

The existence of both standardized and manufacturer-specific codes means that while you can get a general idea of the problem using a basic OBD2 scanner and the standardized portion of the code, diagnosing more complex or brand-specific issues might require more advanced diagnostic tools and knowledge.

For common issues like engine misfires or emissions problems, the standardized codes are incredibly helpful and quite universal in their meaning. However, for problems related to specific vehicle features or intricate system interactions, manufacturer-specific codes become essential, and their interpretation might require access to manufacturer-specific service information.

Exploring the Four Main Types of OBD2 Codes

OBD2 codes are broadly categorized into four main types based on the vehicle system they relate to. Understanding these categories helps narrow down the potential area of the problem.

1. Powertrain Codes (P-Codes)

Powertrain codes, starting with the letter “P,” are the most common type. They indicate problems within the powertrain system, which encompasses the engine, transmission, and related drivetrain components. These codes are crucial for diagnosing issues that affect the vehicle’s power delivery, fuel efficiency, and overall performance.

Example: P0171 – “System Too Lean (Bank 1)”. This standardized powertrain code suggests that the engine is receiving too much air or not enough fuel in Bank 1 (one side of the engine). This could be due to various issues like a vacuum leak, a faulty oxygen sensor, or a problem with the fuel delivery system.

2. Body Codes (B-Codes)

Body codes, starting with “B,” point to problems within the vehicle’s body systems. This category covers a wide range of components related to passenger comfort, convenience, and safety, including:

- Airbags and supplemental restraint systems (SRS)

- Power windows, locks, and seats

- Lighting systems (interior and exterior)

- Climate control (HVAC)

- Anti-theft systems

Example: B0010 – “Driver Front Stage 1 Deployment Control”. This body code indicates a problem with the deployment circuit for the driver’s side front airbag. Such codes are critical for safety as they can indicate malfunctions in essential safety systems.

3. Chassis Codes (C-Codes)

Chassis codes, beginning with “C,” relate to issues in the vehicle’s chassis systems. This category includes systems that contribute to vehicle handling, ride comfort, and braking, such as:

- Anti-lock Braking System (ABS)

- Traction Control System (TCS)

- Electronic Stability Control (ESC)

- Suspension systems (including air suspension)

- Steering systems

Example: C0044 – “Right Rear Wheel Speed Sensor Circuit”. This chassis code indicates a problem with the wheel speed sensor on the right rear wheel. This can affect ABS, TCS, and ESC functionality, impacting vehicle safety and handling.

4. Network Communication Codes (U-Codes)

Network communication codes, starting with “U,” indicate problems within the vehicle’s communication networks. Modern vehicles use complex communication networks (like CAN bus) to allow various electronic control units (ECUs) to communicate with each other. U-codes signal disruptions in this communication.

Example: U0101 – “Lost Communication With TCM (Transmission Control Module)”. This network code indicates that the vehicle’s computer has lost communication with the Transmission Control Module. This type of issue can lead to a wide range of drivability problems as different modules rely on each other for proper operation.

Decoding OBD2 Codes: How to Read and Interpret

Reading OBD2 codes involves using a scan tool, but understanding the structure of the code is key to interpretation. As previously mentioned, the five-character code provides valuable information:

- First Character: System category (P, B, C, U).

- Second Character: Code type (0 – Standardized, 1 – Manufacturer-Specific).

- Third Character: Sub-system (e.g., Fuel, Ignition, etc. for P-codes).

- Fourth and Fifth Characters: Specific fault number.

Example Code Breakdown: P0301

- P: Powertrain (Engine or Transmission related)

- 0: Standardized Code (Universal)

- 3: Ignition System or Misfire

- 01: Cylinder 1

Therefore, P0301 translates to “Cylinder 1 Misfire Detected.” This is a standardized code, so its meaning will be the same across different OBD2-compliant vehicles.

To get a detailed description of a code, you can:

- Consult a Code Reader’s Database: Many OBD2 scanners have built-in databases that provide code definitions.

- Use Online OBD2 Code Lookup Tools: Websites and apps are available where you can enter an OBD2 code and get its description and potential causes.

- Refer to a Repair Manual: Vehicle-specific repair manuals provide comprehensive information on OBD2 codes and diagnostic procedures.

Clearing OBD2 Codes: When and How

Clearing OBD2 codes should generally be done after the underlying issue has been properly diagnosed and repaired. Simply clearing a code without fixing the problem will only temporarily turn off the check engine light, and the code will likely return.

However, there are situations where clearing a code might be necessary, such as after completing a repair or for diagnostic purposes. Here are a few methods:

1. Using an OBD2 Scanner to Clear Codes

Most OBD2 scanners have a “clear codes” or “erase DTCs” function. After connecting the scanner and retrieving codes, you can typically navigate to this option in the scanner’s menu. This method electronically commands the vehicle’s computer to clear the stored codes and turn off the check engine light.

2. Drive Cycle Method

Some codes, especially those related to minor or intermittent issues, might clear themselves after one or more successful “drive cycles.” A drive cycle is a specific set of driving conditions (speed, duration, engine temperature, etc.) that allows the vehicle’s diagnostic system to re-evaluate the system that triggered the code. If the issue is no longer present, the code might clear automatically. However, this method is not reliable for all codes and can take time.

3. Professional Mechanic Assistance

If you are unsure about clearing codes or if the codes reappear after clearing, it’s best to consult a qualified mechanic. Mechanics have advanced diagnostic tools and expertise to accurately diagnose the root cause of the problem and ensure it’s properly fixed, not just masked by clearing the code. They can also clear codes using professional-grade scan tools after repairs are completed.

Important Caution: Avoid clearing codes indiscriminately without addressing the underlying problem. The check engine light and OBD2 codes are valuable indicators of potential issues. Ignoring them can lead to more significant damage and costly repairs down the line.

Preventing OBD2 Codes: Proactive Vehicle Maintenance

Preventing OBD2 codes is always better than dealing with them. Regular and proactive vehicle maintenance is key to minimizing the occurrence of diagnostic trouble codes and keeping your vehicles in optimal condition.

1. Regular Vehicle Maintenance Schedule

Following the manufacturer’s recommended maintenance schedule is crucial. This includes:

- Regular Oil Changes: Fresh, high-quality engine oil is vital for engine lubrication and preventing wear.

- Air and Cabin Filter Replacement: Clean filters ensure proper airflow to the engine and passenger compartment.

- Spark Plug and Ignition System Maintenance: Properly functioning ignition components prevent misfires and ensure efficient combustion.

- Fluid Checks and Flushes: Regularly checking and replacing fluids like coolant, brake fluid, and transmission fluid is essential for system health.

- Brake System Inspections: Regular brake inspections and maintenance ensure safe braking performance.

- Tire Rotations and Inspections: Proper tire maintenance contributes to handling, fuel efficiency, and safety.

2. Using Quality Fuel and Fluids

Using high-quality fuel and fluids as recommended by the vehicle manufacturer is also essential. Low-quality fuel can lead to incomplete combustion, causing engine deposits and emissions issues that trigger OBD2 codes. Similarly, using substandard fluids can lead to premature wear and tear on various vehicle systems.

- Fuel: Choose reputable gas stations and use the correct octane rating for your vehicle.

- Fluids: Use manufacturer-recommended engine oil, transmission fluid, coolant, brake fluid, and power steering fluid.

- Regular Fluid Level Checks: Periodically check fluid levels and top them off as needed.

Managing OBD2 Codes for Fleets: Efficiency and Proactive Maintenance

For fleet managers, efficiently handling OBD2 codes is essential for minimizing vehicle downtime and controlling maintenance costs. Centralized systems and proactive monitoring can significantly streamline OBD2 code management for fleets.

1. Centralized OBD2 Code Tracking Systems

Implementing a centralized system to track OBD2 codes across all fleet vehicles provides a consolidated view of vehicle health. Modern fleet management software and telematics solutions can automatically collect and report OBD2 code data in real-time. This allows fleet managers to:

- Quickly identify vehicles with active codes.

- Track recurring issues across the fleet.

- Generate reports on common fault codes and vehicle maintenance needs.

2. Ongoing Fleet Vehicle Monitoring

Utilizing telematics systems for ongoing monitoring of fleet vehicles provides real-time insights into vehicle performance and diagnostics. These systems can:

- Alert fleet managers immediately when an OBD2 code is triggered.

- Provide location data for affected vehicles.

- Track vehicle parameters related to the code (e.g., engine temperature, speed).

- Enable proactive maintenance scheduling based on code severity and vehicle usage.

3. Prioritization of Repairs Based on Code Severity

Fleet managers should establish a system for prioritizing repairs based on the severity of OBD2 codes. Codes indicating critical safety issues or potential for major damage should be addressed immediately. Less severe codes can be scheduled for repair during routine maintenance intervals. This prioritization ensures efficient allocation of maintenance resources and minimizes vehicle downtime.

In Conclusion

Are Obd2 Codes Universal? The answer is nuanced. While a significant portion of OBD2 codes are standardized and universally applicable across vehicles, manufacturer-specific codes also exist, providing more detailed diagnostics for particular makes and models.

Understanding the structure and types of OBD2 codes empowers vehicle owners and fleet managers to better interpret diagnostic information and take proactive steps for vehicle maintenance and repair. By combining knowledge of OBD2 codes with regular preventative maintenance and efficient fleet management systems, you can ensure the longevity, reliability, and optimal performance of your vehicles.