Monitoring your vehicle’s health is now more accessible than ever, thanks to tools like Arduino and the OBD2 protocol. For car enthusiasts and DIY mechanics, tapping into the On-Board Diagnostics (OBD2) system opens a window into crucial engine and transmission data. Specifically, understanding transmission codes is vital for maintaining your vehicle’s performance and longevity. This article will guide you through using Arduino to read OBD2 transmission codes, focusing on practical applications and code interpretation.

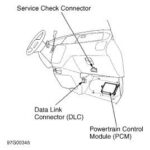

The OBD2 port in your car is a standardized interface that provides access to a wealth of data from your vehicle’s computer system. Among the most valuable data points are transmission codes, which can signal potential issues with your gearbox. By connecting an Arduino to your OBD2 port, you can retrieve and display real-time data, such as transmission temperature, gear status, and torque converter lock status. This allows for proactive maintenance and a deeper understanding of your vehicle’s operation.

To get started, you’ll need an Arduino board, an OBD2 adapter (often CAN bus based), and the necessary libraries to facilitate communication. The process involves sending specific request codes to your vehicle’s ECU (Engine Control Unit) and interpreting the responses. These request codes, often referred to as PIDs (Parameter IDs), are standardized for common parameters but can be manufacturer-specific for more detailed data.

For instance, consider reading transmission temperature. While standard OBD2 PIDs exist, some manufacturers, like Toyota in the example from our source, use custom PIDs for enhanced diagnostics. The original post highlights specific codes for a 2023 Toyota Tacoma, which are invaluable for users with similar models. These codes, like Header 701 Mode 22 PID 1627 for transmission pan temperature, demonstrate the structure of an OBD2 request.

struct canMsg1;

canMsg1.can_id = 0x16;

canMsg1.can_dlc = 8;

canMsg1.data[0] = 0x00;

canMsg1.data[1] = 0x00;

canMsg1.data[2] = 0x00;

canMsg1.data[3] = 0x00;

canMsg1.data[4] = 0x00;

canMsg1.data[5] = 0x00;

canMsg1.data[6] = 0x00;

canMsg1.data[7] = 0x00;

//The send message command: mcp2515.sendMessage(&canMsg1);In this code snippet, the user is configuring a CAN message to send an OBD2 request. The can_id and can_dlc parameters are crucial for CAN bus communication. The header 701 likely refers to the ECU address being targeted, and Mode 22 indicates a request for extended PID data. The PID 1627 is the specific identifier for the transmission pan temperature in this Toyota model. Understanding these components is key to crafting the correct requests for your vehicle.

Furthermore, the example lists other useful transmission-related PIDs:

- Torque converter return oil temp: Header 701 Mode 22 PID 1628

- Transmission current gear: Header 701 Mode 22 PID 1621

- Torque converter lock status: Header 701 Mode 22 PID 1620

These codes, alongside standard OBD2 PIDs, can be integrated into an Arduino sketch to create a custom dashboard displaying real-time transmission data. This data can be invaluable for monitoring transmission health during towing, off-roading, or even daily driving, allowing you to catch potential issues before they escalate into costly repairs.

In conclusion, using Arduino to decode OBD2 transmission codes empowers you with detailed insights into your vehicle’s performance. By understanding the structure of OBD2 requests, utilizing vehicle-specific PIDs, and leveraging the capabilities of Arduino, you can create custom diagnostic tools and enhance your car maintenance practices. Exploring manufacturer-specific forums and databases is often necessary to uncover the precise PIDs for advanced data like transmission temperatures, making community resources invaluable in this endeavor.