For automotive technicians seeking advanced diagnostic capabilities, bidirectional control is a game-changer. It allows you to not just read data from a vehicle’s computer, but also to send commands to test components and systems. Many modern OBD2 scanners, especially when paired with comprehensive databases like Alldata, offer this powerful functionality. Let’s explore how to access and utilize bidirectional controls, turning your OBD2 scanner into an even more effective diagnostic tool.

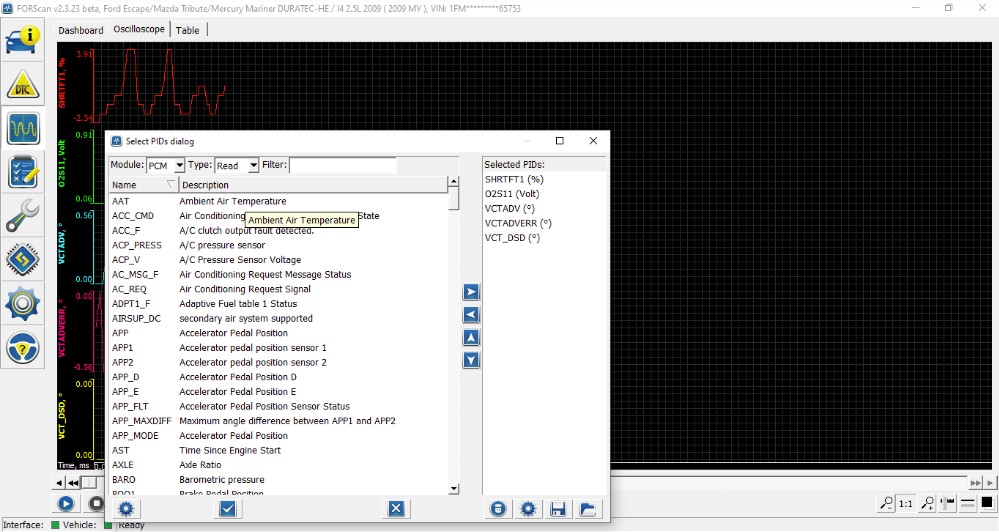

To get started with bidirectional control, the first crucial step is to select the data parameters (PIDs) you want to monitor. This allows you to observe the real-time effects of your commands. Furthermore, you need to choose the specific control function you intend to use. For example, if you’re working on the Variable Camshaft Timing (VCT) system, selecting related PIDs and the VCT control function is essential.

Once you have configured your data monitoring and control selections, the key to initiating bidirectional commands lies in locating and activating the ‘Control’ button on your scanner’s interface. This button often unlocks a menu that allows you to execute output commands and functional tests. It’s important to note that before pressing the ‘Control’ button, ensure you have already loaded the necessary data PIDs and chosen the control functions relevant to the system you are diagnosing.

After pressing ‘Control’, a menu will appear, presenting the available output commands for the selected system. In the VCT system example, you can directly command changes and observe the corresponding data feedback in real-time. This direct interaction is invaluable for pinpointing issues and verifying repairs.

Beyond system-specific controls like VCT, some advanced OBD2 scanners with Alldata integration offer broader functional tests. A prime example is the Commanded Equivalence Ratio function. This powerful tool grants you direct control over the air-fuel ratio, similar to functional tests found in professional scan tools for brands like Toyota and Nissan. This level of control, often absent even in advanced scanners like the Modis Ultra, demonstrates the enhanced capabilities offered by systems that integrate comprehensive data with bidirectional control.

It’s worth noting that the effectiveness of bidirectional controls can depend on several factors, including the specific test being run and the vehicle’s state. For instance, some tests, like injector disable tests for relative compression analysis, might only function correctly when initiated with the engine off (KOEO – Key On Engine Off). Furthermore, attempting to command values outside of a system’s physical limits might cause the test to terminate. Understanding these nuances and experimenting with different functions are key to mastering bidirectional control with your Alldata Obd2 Scanner.

In conclusion, bidirectional control significantly expands the diagnostic potential of your Alldata OBD2 scanner. By correctly configuring data monitoring, locating the ‘Control’ function, and understanding the nuances of different tests, you can effectively command vehicle systems, perform in-depth diagnostics, and streamline your repair processes. Explore the capabilities of your scanner and unlock the power of bidirectional control for more efficient and accurate automotive servicing.