So, you’re diving into the world of engine modifications and considering an OBD1 conversion for your OBD2 BMW? You’ve probably heard whispers of performance gains and simpler engine management. But as you delve deeper, questions arise, especially about the nitty-gritty details like wiring. A common question in forums and garages alike is: “Are Obd2 Ignition Wires Different Than Obd1?”

The short answer is yes, and no. While the fundamental function of ignition wires – to deliver spark to your engine – remains the same, there are crucial differences in the wiring and components between OBD1 and OBD2 ignition systems, especially when it comes to BMWs of the 90s. This article will break down these differences, guiding you through the complexities of an OBD2 to OBD1 conversion, focusing on the ignition system and beyond.

Let’s get straight to the point: If you’re contemplating an OBD1 conversion, understanding the ignition wiring is paramount. It’s not just about swapping wires; it’s about understanding a system-wide change impacting various engine components.

Decoding OBD1 and OBD2 Ignition Systems

Before we get our hands dirty, let’s understand what OBD1 and OBD2 mean in the context of ignition systems.

-

OBD1 (On-Board Diagnostics 1): The earlier generation of automotive diagnostic systems. In BMWs of the early to mid-90s (like the E36 325i), OBD1 systems are simpler, with less stringent emission controls and engine management. They typically use a ‘red label’ ECU (like the 413) which is desirable for conversions due to their non-EWS (immobilizer) nature.

-

OBD2 (On-Board Diagnostics 2): A more advanced system mandated in the US starting in 1996. OBD2 systems, found in later E36 models like the 1999 M3, are more complex, featuring enhanced diagnostics, stricter emission controls (including secondary air pumps and post-catalyst oxygen sensors), and often include immobilizer systems like EWS (Electronic Drive-away Warning System).

The core difference impacting ignition wiring arises from these system architectures and their respective engine management strategies.

Key Ignition Components and Wiring Differences in OBD Conversions

When converting from OBD2 to OBD1, you’re not just changing the engine management computer (ECU); you’re essentially rewiring and replacing a significant portion of your engine’s electrical system. Here’s a breakdown of the critical components and wiring aspects where differences emerge:

1. Valve Cover and Coil Packs: A Visual and Wiring Shift

One of the first visual cues of the OBD1 vs OBD2 difference lies in the valve cover and coil pack setup.

-

OBD2 Valve Cover & Coils: OBD2 valve covers on engines like the S52 are designed with wiring entering from the passenger side. The OBD2 coil packs are compatible with the OBD2 harness.

-

OBD1 Valve Cover & Coils: OBD1 systems, like those on the M50, have valve covers designed for wiring to enter from the driver’s side. While both OBD1 and OBD2 coil versions can plug into the OBD1 harness electrically, the physical routing and mounting differ.

Here’s a closer look at the coil differences:

Wiring Implication: If you retain your OBD2 valve cover (as many do), you might need to slightly modify it (using a Dremel tool) to accommodate the OBD1 harness wiring routing. Alternatively, switching to an OBD1 valve cover necessitates using OBD1 coil packs, though both are electrically compatible with the OBD1 harness.

2. Vanos Solenoid: Connector Compatibility

The Vanos (variable valve timing) solenoid wiring also presents a minor but crucial difference.

-

OBD2 Vanos Solenoid: The OBD2 Vanos solenoid wire connector is shorter than its OBD1 counterpart.

-

OBD1 Vanos Solenoid: OBD1 solenoids have a longer wire connector.

Wiring Implication: To use your OBD2 Vanos solenoid with an OBD1 harness, you’ll likely need to extend the wiring. BMW part # 12-52-2-274-971 (a transmission harness) is often used as it has compatible connectors for extending the Vanos solenoid wiring.

{width=640 height=425}

*alt text: Image of a BMW transmission harness (part number 12-52-2-274-971) used to extend the OBD2 Vanos solenoid wiring for OBD1 conversion, showing connector details.*3. Coolant Temperature Sensors: From One to Two

OBD systems differ in how they monitor coolant temperature.

-

OBD2 Coolant Temp Sender: OBD2 systems typically use a single coolant temperature sender, located on the cylinder head.

-

OBD1 Coolant Temp Senders: OBD1 systems utilize two coolant temperature senders on the cylinder head.

Wiring Implication: You have options here. You can splice the OBD1 harness wiring and use your OBD2 single temp sender, or opt for a cleaner solution using a coolant temp sender wiring adapter from aftermarket suppliers like Turner Motorsport.

4. Crank Position Sensor: Location and Type

The location and type of crank position sensors are also different.

-

OBD2 Crank Position Sensor: Located on the engine block near the starter motor.

-

OBD1 Crank Position Sensor: Located on the timing cover, mounted on a circular tab.

Wiring Implication: You must use an OBD1 crank position sensor for the conversion, and simply leave the OBD2 sensor in place to plug the hole in the block. This is a direct component swap rather than a pure wiring modification, but crucial for ignition timing signals.

5. Oxygen Sensors: Fewer Sensors, Different Wiring

OBD1 and OBD2 systems have significant differences in oxygen sensor setups, directly impacting the wiring.

-

OBD2 Oxygen Sensors: OBD2 systems employ four oxygen sensors: two pre-catalyst and two post-catalyst, for comprehensive emission monitoring.

-

OBD1 Oxygen Sensor: OBD1 systems use only one pre-catalyst oxygen sensor.

Wiring Implication: During an OBD1 conversion, you eliminate the secondary air pump and the post-catalyst oxygen sensors entirely. You’ll need to plug the ports where the post-cat sensors were located. The OBD1 harness will only accommodate a single pre-catalyst oxygen sensor.

6. EWS (Immobilizer) and Ignition Issues

EWS, BMW’s anti-theft system, adds another layer of complexity, particularly with ignition.

-

OBD2 with EWS: Many OBD2 BMWs, especially later models, incorporate EWS, which can interfere with ignition if not addressed during a conversion.

-

OBD1 without EWS (typically): OBD1 ECUs, especially the ‘red label’ 413, are often sourced from non-EWS cars, simplifying the immobilizer aspect.

Wiring Implication: Even with a non-EWS OBD1 ECU, ignition issues related to EWS can arise. A common solution involves a simple wiring modification: cutting wire #66 on the main engine harness connector to the ECU. This wire is typically solid green or black/violet.

7. Power Distribution and Grounding: Careful Reconnection

While not strictly “ignition wires,” power and ground connections are vital for the entire electrical system, including ignition.

-

OBD2 Power Distribution: OBD2 systems have specific power distribution box locations and grounding points.

-

OBD1 Power Distribution: OBD1 harnesses have different power and ground connection points.

Wiring Implication: Careful attention must be paid to power and ground connections. Relocating the OBD2 power distribution box might be necessary to reach the OBD1 harness power connections. Labeling wires during disassembly and referencing wiring diagrams (like the Bentley manual) are crucial to avoid electrical issues and ensure proper ignition system power.

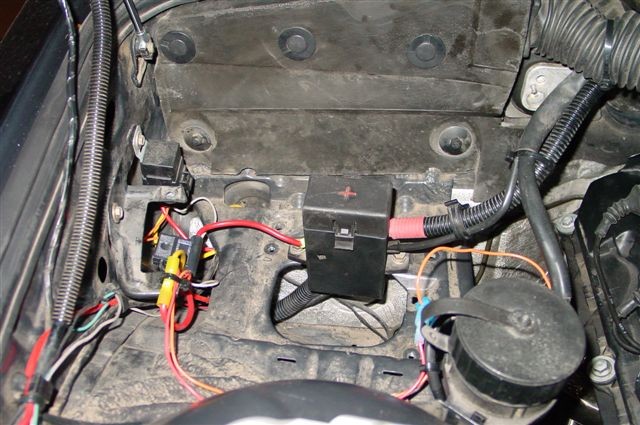

{width=640 height=425}

*alt text: Image showing the relocated OBD2 power terminal box in a BMW engine bay after OBD1 conversion, highlighting the tight fit and adapted positioning.*8. General Harness and Connector Labeling: Essential for Success

The entire OBD1 harness swap is a significant undertaking.

-

OBD2 Harness: Complex, integrated with OBD2 specific sensors and systems.

-

OBD1 Harness: Simpler, designed for OBD1 sensors and systems.

Wiring Implication: Thoroughly labeling connectors on both the OBD2 harness before removal and the OBD1 harness before installation is paramount. This, combined with wiring diagrams, is essential for correctly connecting all components, including the ignition system elements.

{width=640 height=425}

*alt text: Image of a meticulously labeled OBD1 engine harness prepared for installation during an OBD2 to OBD1 conversion, emphasizing the importance of organization.*Performance Gains and Dyno Results: The OBD1 Conversion Payoff

The primary motivation behind many OBD1 conversions is the potential performance gain, often attributed to the less restrictive M50 intake manifold used in OBD1 systems.

-

OBD2 Intake Manifold (M52/S52): Considered more restrictive than OBD1 manifolds.

-

OBD1 Intake Manifold (M50): Known for better airflow and performance potential.

Performance Result: The original article details dyno results showcasing the performance increase after the OBD1 conversion, along with other modifications:

- Initial Dyno: 253 RWHP, 228 TQ (running rich)

- Revised Dyno (after chip tuning): 262 RWHP, 230 TQ

These numbers demonstrate a tangible performance improvement, validating the efforts of the OBD1 conversion.

Conclusion: More Than Just Wires – A Systemic Change

So, “are OBD2 ignition wires different than OBD1?” Yes, in the broader context of the entire ignition system and engine management. It’s not just about the wires themselves but the components they connect to, the signals they carry, and the overall system architecture.

An OBD2 to OBD1 conversion is not a simple “electronics swap.” It’s a comprehensive modification requiring careful planning, component sourcing, and meticulous wiring work. Understanding the ignition system differences, along with the nuances of fuel delivery, cooling, and other engine systems, is crucial for a successful conversion.

By addressing the wiring differences in coil packs, Vanos, coolant sensors, crank sensors, oxygen sensors, and considering factors like EWS and power distribution, you can navigate the complexities of an OBD1 conversion and potentially unlock performance gains for your OBD2 BMW. Remember to consult wiring diagrams, label everything, and proceed methodically. Good luck with your conversion!