Encountering the OBD2 code P2609 can be perplexing, but understanding its root cause is the first step towards resolving it. This code signals an issue within your vehicle’s intake air heater circuit, a crucial component, especially in diesel engines, designed to ensure smooth starts and optimal engine performance in colder conditions. If you’ve recently pulled a P2609 code, this guide will walk you through the diagnostic process to pinpoint the problem and get your vehicle running smoothly again.

Understanding the P2609 Code

The P2609 code is formally defined as “Intake Air Heater ‘A’ Circuit Malfunction.” This indicates that the Engine Control Module (ECM) has detected an anomaly in the electrical circuit responsible for operating the intake air heater. Specifically, the ECM monitors the voltage drop when the intake air heater is activated. If this voltage drop is not detected within the first 15 seconds of engine operation, the P2609 code is triggered.

The intake air heater’s primary function is to warm the incoming air to the engine during cold starts. This preheating of air aids in better combustion, reduces white smoke, and ensures a smoother engine start, particularly in diesel engines operating in cold climates. While gasoline engines may also use intake air heaters in some applications, this code is more commonly associated with diesel vehicles.

Symptoms Associated with the P2609 Code

While a P2609 code might not always present obvious symptoms, especially in moderately warm weather, you might observe some tell-tale signs:

- Check Engine Light: The most immediate symptom is the illumination of your vehicle’s check engine light on the dashboard.

- Hard Starts in Cold Weather: In colder temperatures, you might experience difficulty starting your engine. This is because the intake air heater is not functioning to pre-warm the air for optimal combustion.

- White Smoke on Startup: Especially in diesel engines, you might notice excessive white smoke emanating from the exhaust during startup, indicating incomplete combustion due to cold air intake.

- Reduced Engine Performance in Cold Conditions: In very cold weather, if the intake air heater is malfunctioning, you might experience slightly reduced engine performance until the engine warms up.

It’s important to note that in milder temperatures (around 40°F or 4°C as mentioned in the original post), the symptoms might be subtle or even unnoticeable, except for the presence of the OBD2 code itself.

Diagnosing the P2609 Code: A Step-by-Step Guide

Troubleshooting the P2609 code requires a systematic approach to pinpoint the faulty component. Here’s a diagnostic procedure based on standard troubleshooting practices:

1. Inspect the Intake Air Heater Resistance

The first step is to check the resistance of the intake air heater itself. This will determine if the heater element is intact and not open-circuited.

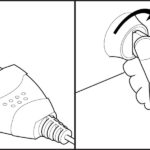

- Action: Use a multimeter to measure the resistance between the supply terminal and the ground terminal of each intake air heater.

- Expected Outcome: The resistance should be less than 10 Ohms.

- If Resistance is High (Open Circuit): Replace the faulty intake air heater.

2. Check the Intake Air Heater Ground Circuit

A proper ground connection is essential for the intake air heater circuit to function. This step verifies the integrity of the ground path.

- Action: Measure the resistance between the intake air heater terminal and the intake manifold ground connection.

- Note: The intake air heater often grounds through conductive gaskets.

- Expected Outcome: The resistance should be less than 10 Ohms.

- If Resistance is High: Inspect and repair any open or high resistance in the ground circuit. Ensure the conductive gaskets are in good condition and properly installed. Replace if necessary.

3. Examine the Battery Cable from Relay to Intake Air Heater

The battery cable supplying power from the relay to the intake air heater can be a source of issues if it’s damaged or corroded.

- Action: Measure the resistance of the battery cable between the intake air heater and the intake air heater relay for both heaters (if applicable).

- Expected Outcome: The resistance should be less than 10 Ohms.

- If Resistance is High: Repair or replace any open or high resistance in the battery cable connecting the relay to the heater.

4. Verify the Battery Cable to the Relay

The power supply to the intake air heater relay itself needs to be verified.

- Action: Measure the resistance of the battery cable between the battery and the intake air heater relay for both relays (if applicable).

- Expected Outcome: The resistance should be less than 10 Ohms.

- If Resistance is High: Replace the battery cable running from the battery to the intake air heater relay.

5. Test the Intake Air Heater Relay(s) – Relay #1

The intake air heater relays are responsible for switching power to the heaters. Testing them is crucial.

- Action: Disconnect the signal wire from relay #1. Apply 12V directly from the battery positive terminal to the signal terminal of the relay using a jumper wire.

- Expected Outcome: The relay should click audibly when 12V is applied, indicating it is functioning mechanically.

- If Relay Does Not Click: Replace relay #1.

6. Test the Intake Air Heater Relay(s) – Relay #2

If your vehicle utilizes a second intake air heater relay, it also needs to be tested.

- Action: Disconnect the signal wire from relay #2. Apply 12V directly from the battery positive terminal to the signal terminal of relay #2 using a jumper wire.

- Expected Outcome: The relay should click when 12V is applied.

- If Relay Does Not Click: Replace relay #2.

- If Relay Clicks: If the relay clicks but the issue persists, suspect an intermittent condition in the wiring or ECM control signal. Further diagnostic steps for intermittent issues may be required, potentially involving checking wiring harnesses for chafing or corrosion and verifying the ECM’s control signal output.

Conclusion

Troubleshooting the P2609 code involves a systematic process of elimination, primarily focusing on the intake air heater circuit’s electrical components. By methodically checking the resistance of the heater itself, the ground circuit, the power supply cables, and the relays, you can effectively diagnose and repair the issue. Remember to always consult your vehicle’s service manual for specific wiring diagrams and component locations. If you are uncomfortable performing these diagnostic steps, it is always recommended to seek assistance from a qualified automotive technician to ensure accurate diagnosis and repair.