Understanding your 2012 Dodge Charger’s onboard diagnostics system is crucial for modern car owners. OBD2 (On-Board Diagnostics II) is a standardized system in vehicles that allows you to access a wealth of information about your car’s health and performance. Parameter IDs (PIDs) are codes used to request specific data from your vehicle’s computer via the OBD2 system. While the term “obd2-obd11 pid c7-00” might contain a slight misunderstanding (likely referring to OBD-II and potentially an incorrect PID), this guide will clarify everything you need to know about accessing and interpreting OBD2 PIDs in your 2012 Dodge Charger.

OBD2 is essentially your car’s built-in self-diagnostic system. It’s designed to monitor various components and systems in your vehicle, from the engine and transmission to emissions and more. This system is invaluable for both car owners and mechanics, providing insights into vehicle operation and potential issues. When your “check engine light” (Malfunction Indicator Light – MIL) illuminates, it’s often an OBD2 code that points to the problem.

For your 2012 Dodge Charger, like most modern vehicles, OBD2 compliance means there’s a standardized connector, usually located under the dashboard near the steering column. Mechanics use OBD2 scan tools to connect to this port and read diagnostic trouble codes (DTCs) and live data. But you too can leverage this system to understand your car better.

An important standard governing OBD2 is SAE J1979. This standard defines a set of common OBD2 PIDs that are publicly available. Tools like OBD2 scanners, OBD2 interfaces, and data loggers can send requests to your Dodge Charger using these PIDs. By sending specific CAN bus frames through the OBD2 connector, you can request data for parameters like engine speed, vehicle speed, engine temperature, and much more.

For instance, to request the Vehicle Speed PID (which is PID ‘0D’ in hexadecimal), a tool would send a CAN frame with a specific ID and data payload. If your 2012 Dodge Charger supports this PID, it will respond with another CAN frame containing the requested vehicle speed data in hexadecimal format. This data then needs to be decoded using scaling and offset factors to get the physical value in units like km/h or mph.

This guide provides an overview of OBD2 PIDs, focusing on how they are structured and how you can use them to understand data from your 2012 Dodge Charger. We’ll explore the programmatic formats for working with OBD2 data and provide a table of common OBD2 PIDs.

If you’re involved in OBD2 data logging or analysis for your Dodge Charger or other vehicles, feel free to contact us for expert advice and solutions.

Understanding OBD2 PID Formats Programmatically

For those who want to delve deeper into OBD2 data, especially for logging and analysis, understanding the programmatic formats is key. OBD2 data isn’t just a simple number; it’s transmitted in a structured way via CAN bus frames. To effectively work with this data, especially if you are using tools like data loggers or interfaces, you’ll likely encounter formats like DBC and CSV.

An OBD2 DBC file (CAN database) is used by many CAN bus software tools to decode raw CAN frames that contain OBD2 PID responses. Imagine recording data from your 2012 Dodge Charger using an OBD2 data logger. The raw data will be in CAN frames, which are essentially streams of hexadecimal numbers. A DBC file acts as a dictionary, telling your software how to interpret these numbers. It defines the PIDs, their bit positions within the CAN frame, scaling factors, offsets, and data types. This allows software to automatically translate the raw CAN data into human-readable values like “Engine Speed: 800 RPM” or “Coolant Temperature: 90°C”.

J1939 data pack

J1939 data pack

Similarly, an OBD2 CSV (Comma Separated Values) file contains much of the same information as a DBC file, but in a text-based table format. CSV files are useful if you’re developing your own scripts or programs to decode OBD2 data from scratch. You can easily parse a CSV file to extract the PID definitions, scaling, and offsets needed for your decoding algorithms.

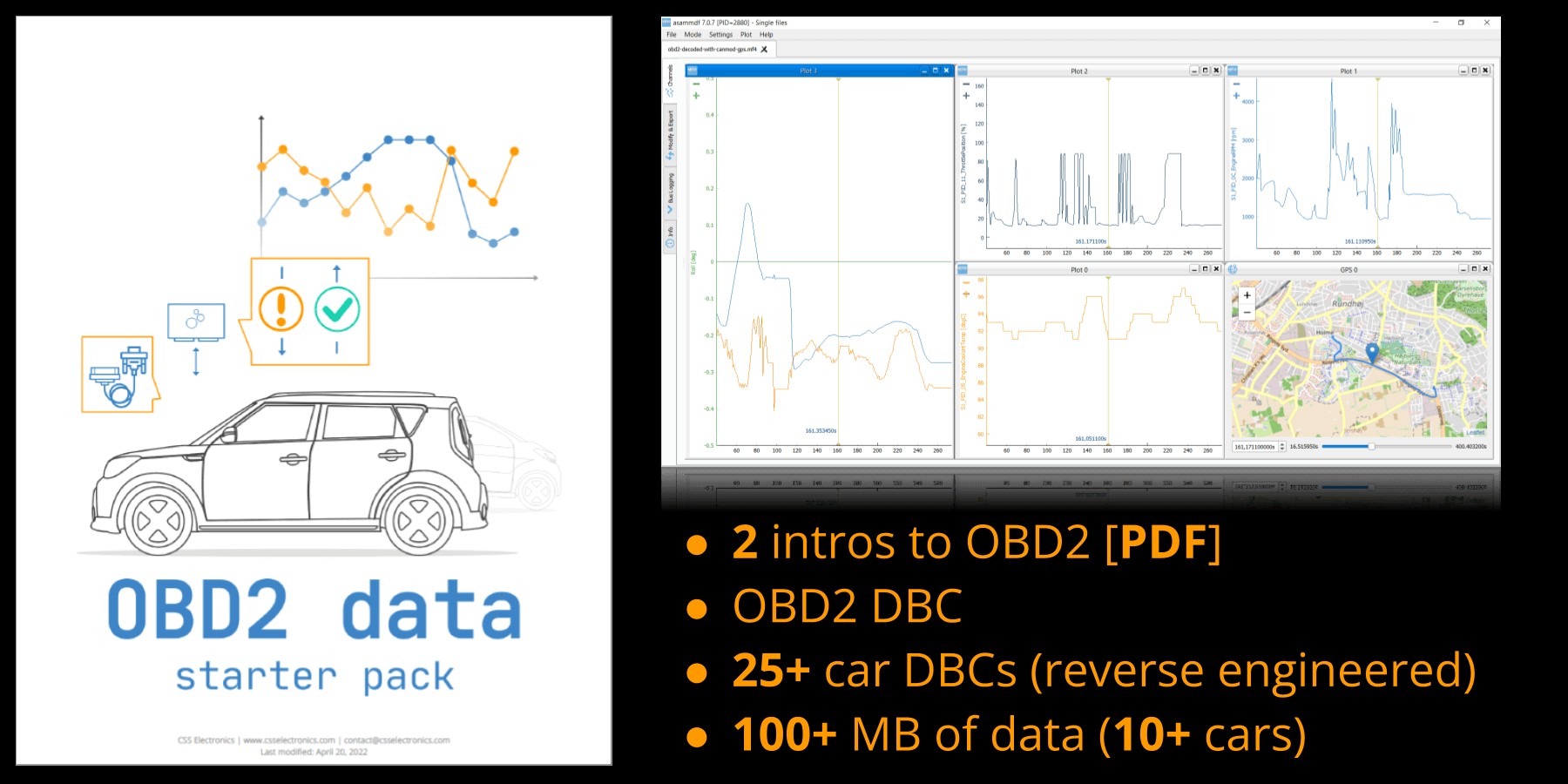

If you’re interested in experimenting with real OBD2 data from vehicles, including Dodge Chargers (though specific 2012 Dodge Charger data may vary), you can find sample OBD2 data online. Tools like the asammdf GUI can be used to load and analyze MF4 log files (a common format for CAN data) and use DBC files to decode the raw data into understandable signals. Furthermore, open-source Python APIs are available that allow you to programmatically load and decode CAN/OBD2 data, making it possible to create custom dashboards or telematics applications.

You can explore resources for DBC files, CSV tables, sample data, and software tools to further your understanding and practical application of OBD2 data analysis.

OBD2 PID Table and Interpretation for Your 2012 Dodge Charger

Understanding the OBD2 PID table is essential for interpreting the data you retrieve from your 2012 Dodge Charger. While you can find various OBD2 PID tables online, some can be less user-friendly. A well-structured table, similar to those used in CAN database files (DBC files), provides a clear breakdown of each PID and how to decode its data.

These tables typically provide information like the PID number (in decimal and hexadecimal), the parameter name, bit start, bit length, scale factor, offset, minimum and maximum values, and the unit of measurement. OBD2 uses big-endian byte ordering. This means when you extract the data bytes from an OBD2 response frame, you can directly convert the hexadecimal representation to a decimal value. This decimal value is often referred to as the “raw value.” To get the actual physical value (e.g., engine speed in RPM), you apply a linear equation using the scale and offset factors provided in the PID table.

Let’s take an example relevant to your 2012 Dodge Charger: Engine Speed (PID 0C). If you send a request for PID 0C and receive a response data payload like:

04 41 0C <span>0A 0C</span> AA AA AAThe bytes 0A 0C (highlighted) contain the engine speed data. Converting the hexadecimal value 0A0C to decimal gives you 2572. Referring to the OBD2 PID table for Engine Speed, you’ll find a scale factor of 0.25 and an offset of 0. The calculation to get the physical engine speed is:

Physical Value = Offset + (Scale * Raw Decimal Value)

Engine Speed = 0 + (0.25 * 2572) = 643 RPMThis calculation method applies to most OBD2 PIDs that represent physical quantities. However, some PIDs are “encoded,” meaning their values represent statuses or flags rather than direct measurements. For these, you’ll need to consult specific documentation, such as the Wikipedia OBD2 PID overview, for decoding instructions. The PID table below focuses on Service 01 PIDs, which are the most commonly used for real-time data acquisition in OBD2 applications and very relevant for diagnosing and monitoring your 2012 Dodge Charger.

| PID dec | PID hex | Name | Bit start | Bit length | Scale | Offset | Min | Max | Unit |

|---|---|---|---|---|---|---|---|---|---|

| 0 | 00 | PIDs supported [01 – 20] | 31 | 32 | 1 | 0 | Encoded | ||

| 1 | 01 | Monitor status since DTCs cleared | 31 | 32 | 1 | 0 | Encoded | ||

| 2 | 02 | Freeze DTC | 31 | 16 | 1 | 0 | Encoded | ||

| 3 | 03 | Fuel system status | 31 | 16 | 1 | 0 | Encoded | ||

| 4 | 04 | Calculated engine load | 31 | 8 | 1/2.55 | 0 | 0 | 100 | % |

| 5 | 05 | Engine coolant temperature | 31 | 8 | 1 | -40 | -40 | 215 | degC |

| 6 | 06 | Short term fuel trim (bank 1) | 31 | 8 | 1/1.28 | -100 | -100 | 99 | % |

| 7 | 07 | Long term fuel trim (bank 1) | 31 | 8 | 1/1.28 | -100 | -100 | 99 | % |

| 8 | 08 | Short term fuel trim (bank 2) | 31 | 8 | 1/1.28 | -100 | -100 | 99 | % |

| 9 | 09 | Long term fuel trim (bank 2) | 31 | 8 | 1/1.28 | -100 | -100 | 99 | % |

| 10 | 0A | Fuel pressure (gauge pressure) | 31 | 8 | 3 | 0 | 0 | 765 | kPa |

| 11 | 0B | Intake manifold absolute pressure | 31 | 8 | 1 | 0 | 0 | 255 | kPa |

| 12 | 0C | Engine speed | 31 | 16 | 0.25 | 0 | 0 | 16384 | rpm |

| 13 | 0D | Vehicle speed | 31 | 8 | 1 | 0 | 0 | 255 | km/h |

| 14 | 0E | Timing advance | 31 | 8 | 0.5 | -64 | -64 | 64 | deg |

| 15 | 0F | Intake air temperature | 31 | 8 | 1 | -40 | -40 | 215 | degC |

| 16 | 10 | Mass air flow sensor air flow rate | 31 | 16 | 0.01 | 0 | 0 | 655 | grams/sec |

| 17 | 11 | Throttle position | 31 | 8 | 1/2.55 | 0 | 0 | 100 | % |

| … | … | … | … | … | … | … | … | … | … |

| 31 | 1F | Run time since engine start | 31 | 16 | 1 | 0 | 0 | 65535 | seconds |

| … | … | … | … | … | … | … | … | … | … |

| 92 | 5C | Engine oil temperature | 31 | 8 | 1 | -40 | -40 | 215 | degC |

| … | … | … | … | … | … | … | … | … | … |

| 124 | 7C | Diesel particulate filter – temperature | 31 | 16 | 0.1 | -40 | -40 | 6514 | degC |

| … | … | … | … | … | … | … | … | … | … |

(Table truncated for brevity, refer to the original article for the full table)

Conclusion

Understanding OBD2 PIDs is a powerful tool for anyone wanting to diagnose, monitor, or analyze their 2012 Dodge Charger’s performance. By using OBD2 scanners, interfaces, and data loggers, and by understanding the structure and decoding of PIDs, you can gain valuable insights into your vehicle’s operation. Whether you are a car enthusiast, a mechanic, or an automotive engineer, mastering OBD2 PIDs opens up a world of automotive data and diagnostic possibilities. Explore the resources provided and start decoding your Dodge Charger’s data today!

Recommended Resources

OBD2 EXPLAINED – A SIMPLE INTRO

OBD2 DATA LOGGER – RECORD YOUR CAR

CUSTOM TELEMATICS DASHBOARDS

[